News

NewsHow can you locate the best plate drilling machine available out there?

How can you locate the best plate drilling machine available out there?

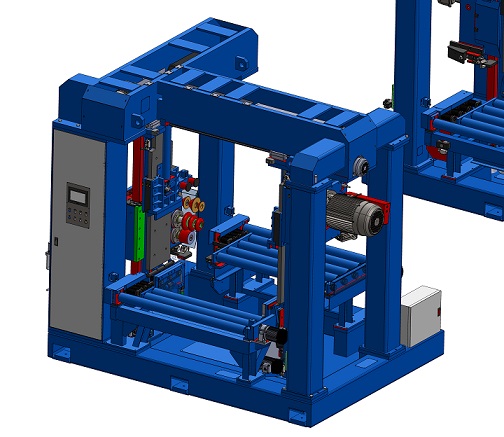

Are you in need of a plate drilling machine? Then you might notice that multiple choices are available for your purchase in the market. It is important to locate the best plate drilling machine out of what is available. Then you can get your specific requirements catered without encountering any challenge. We will share some useful tips with you on how to locate the best plate drilling machine available out there.

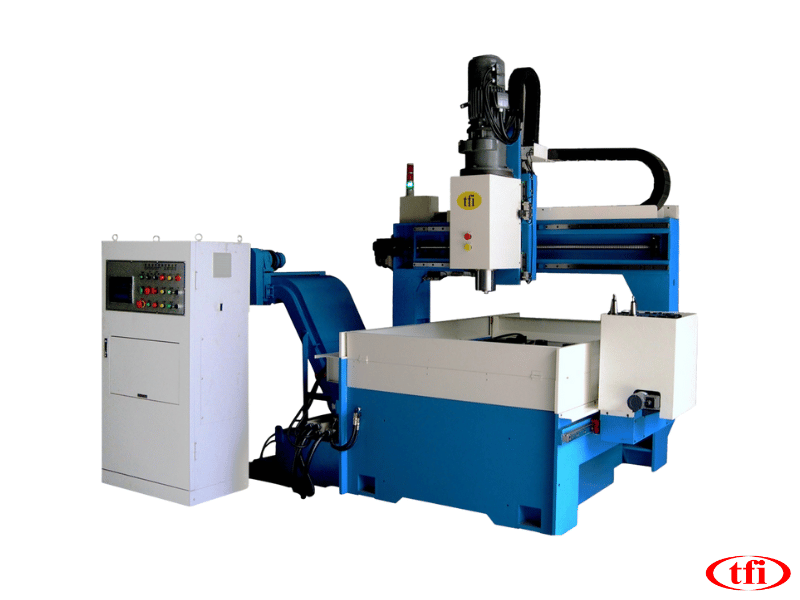

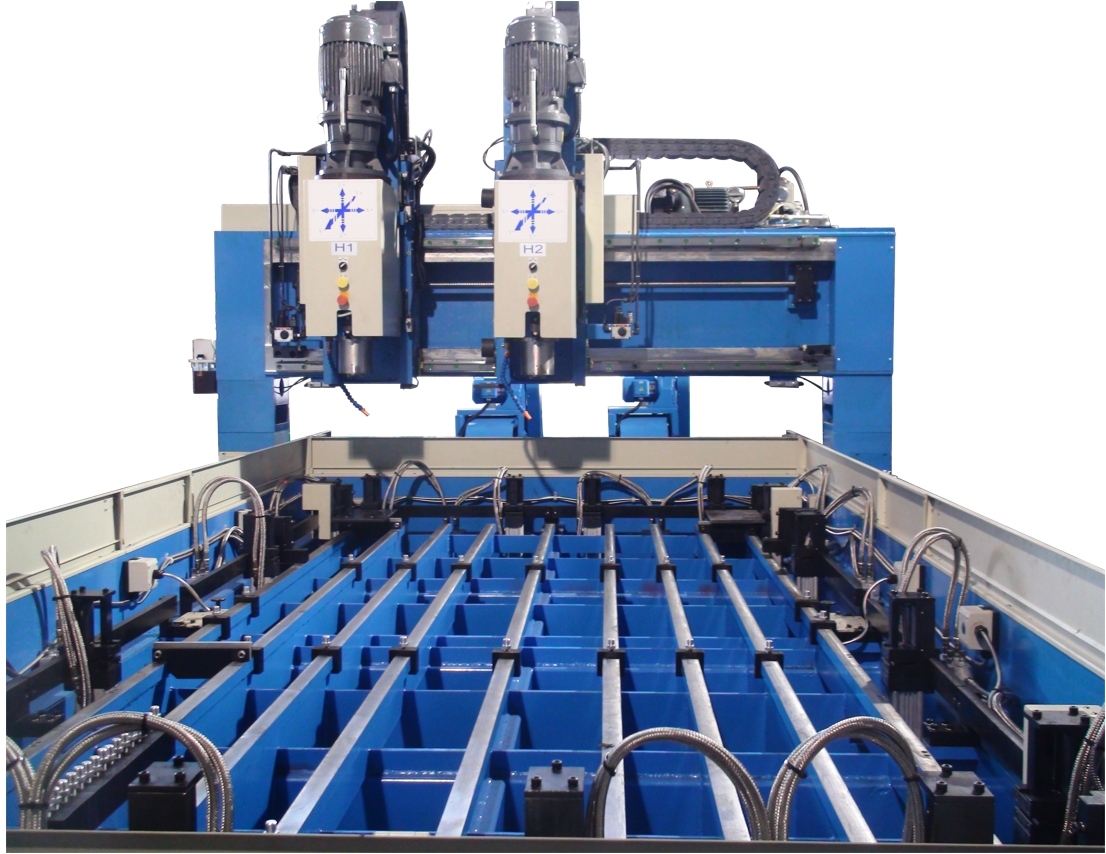

- Take a look at the table width

One of the very first things that you will need to consider at the time of buying a CNC drilling machine is the width of the table. This will help you with getting enough space, which can be useful as you proceed with your applications. In general, we encourage you to purchase a CNC drilling machine that offers a workstation of width at least 1600mm. Then you will never come across any situations where you will complain about lack of width available on the table. That’s because this is a decent width, and it will help you to get most of your work done without a challenge. You will even be able to overcome load deflection problems without an issue. Moreover, it will assist you to ensure the functionality of X-axis synchronous motion of the machine.

- Focus on the connection mode options

There are multiple connection modes available in a CNC drilling machine. You will also need to take a look at it at the time of purchasing the best CNC drilling machine for your needs. For example, it is better if you can get a drilling machine that has an integral structure of a side hanging table and a bed. Moreover, it should also have a small, occupied area and a compact structure. You will be able to reduce your expenses while saving effort on installation.

- Take a look at the plate size selection

The next most important things you should consider is the plate size selection. Depending on your preferences, you can make a selectin in here. It is better if you can double check on your requirement and pick the best product available out there. For example, it is a good idea to pick a sheet that offers a selection size of 2000 mm x 1500 mm x 40 mm. You may also think about purchasing a drilling machine that comes along with a double work table. This will help you to enhance overall utilization rate of the equipment that you are processing.

- Don’t ignore the drilling diameter

You should never ignore the drilling diameter as you buy a plate drilling machine. This is a decision that you should make according to the preferred borehole diameter. The maximum pore size that you can get in a plate drilling machine would be 50mm. However, there are certain drilling machines, which are capable of processing a diameter of up to 90mm.

- Take a look at the accuracy and number of drilling holes you want

Last but not least, you will need to take a look at the accuracy and number of drilling holes you want in the plate. There are low speed drills as well as high-speed drills available. The speed of a high speed drill would reach up to 6,000 rpm. This would surely help you to enhance the overall efficiency of your drilling work. It is better if you can go for a drill that comes with a better speed as much as you can.

Keep these tips in mind and buy the best plate drilling machine available out there.

Products

Plate Drilling Machine

Rail Type Bridge Plate Drilling Machine

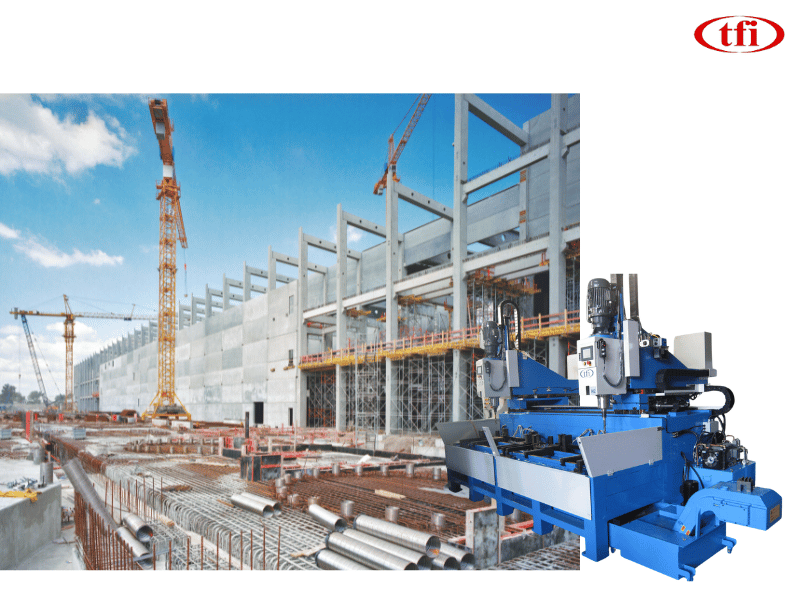

Beam Line Drilling Machine

Laser Marking Machine

- H-Beam Bevelling machine

Products - Plate Drilling Machine

- Rail Type Bridge Plate Drilling Machine

- Beam Line Drilling Machine

- Laser Marking Machine

- Beam line stamper

- H-Beam Scallop & Beveling machine

- Plate beveling machine

- Auto Arm Welder

- Pipe Notcher

- Drill Grinder

- Magnetic Core Drilling Machine

- Remolift

- Shear Wrench

- H-Beam Rotater