News

News7 Ways Drilling Machines Revolutionize Steel Fabrication in Construction

7 Ways Drilling Machines Revolutionize Steel Fabrication in Construction

Introduction

In the construction industry, steel is the backbone of modern infrastructure, from skyscrapers to bridges. The fabrication of steel components demands precision, efficiency, and reliability. Drilling machines have played a transformative role in meeting these needs, revolutionizing how steel fabrication is carried out in construction projects. Trinkle Enterprise Co., Ltd., a leading provider of advanced drilling solutions, offers innovative machines that streamline steel processing and enhance productivity. In this article, we explore seven key ways drilling machines are revolutionizing steel fabrication in construction.

1. Unmatched Precision for Structural Integrity

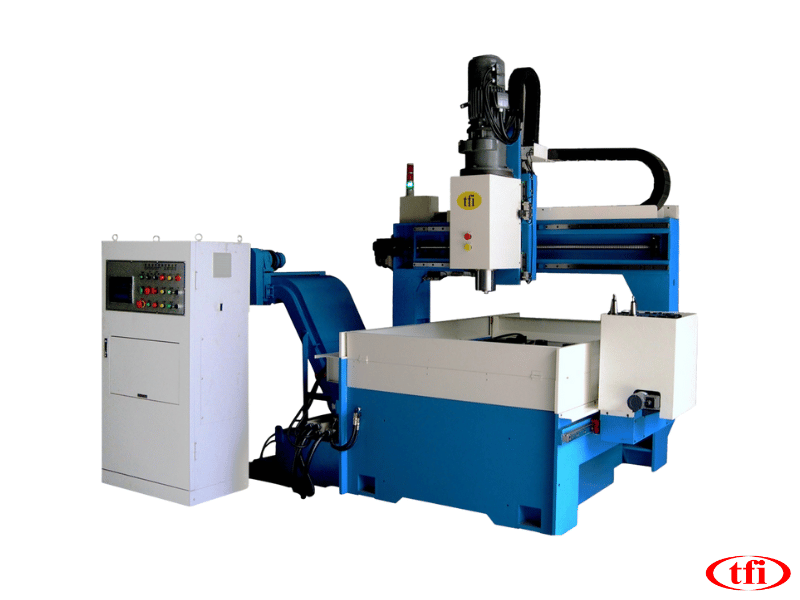

Modern drilling machines, especially CNC-controlled models, ensure holes are drilled with extreme precision. Accurate hole placement is crucial for bolting and connecting steel beams and plates, ensuring structural integrity and safety in buildings and infrastructure.

Benefit:

- Reduces Errors: Precision drilling minimizes the risk of misalignment, which could compromise the stability of structures.

- Consistency: Automated drilling ensures every hole meets exact specifications, maintaining uniformity across all components.

2. Increased Efficiency with Automation

Automated drilling machines drastically reduce manual labor and processing time. CNC technology allows for pre-programmed drilling patterns, enabling machines to work continuously with minimal supervision.

Benefit:

- Faster Project Timelines: Accelerates the fabrication process, helping projects stay on schedule.

- Higher Throughput: Machines like the DNC series from Trinkle Enterprise Co., Ltd. can handle large volumes of steel plates and beams quickly and efficiently.

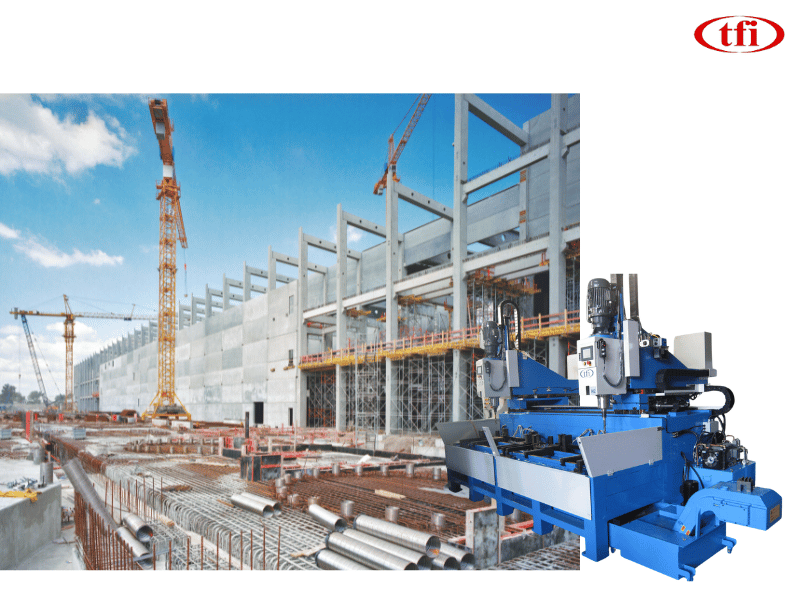

3. Versatility in Handling Various Steel Components

Drilling machines are capable of processing a wide range of steel components, including beams, plates, and columns of different sizes and thicknesses. This versatility is essential for modern construction projects that require diverse steel elements.

Benefit:

- Adaptability: Machines can switch between different workpieces, from large H-beams to stacked plates, without extensive reconfiguration.

- Multiple Applications: Suitable for high-rise buildings, bridges, industrial facilities, and more.

4. Cost Reduction Through Enhanced Productivity

Investing in modern drilling machines leads to significant cost savings by reducing manual labor, minimizing errors, and speeding up production. The quick-change tool systems further reduce downtime, improving overall productivity.

Benefit:

- Lower Labor Costs: Automation reduces the need for extensive manual labor.

- Minimized Waste: Precision drilling reduces material waste caused by errors or rework.

5. Improved Safety Standards

Automated drilling machines improve workplace safety by reducing direct human interaction with high-speed drilling operations. Features like hydraulic or servo-driven feeding systems enhance control and minimize the risk of accidents.

Benefit:

- Safer Work Environment: Operators can manage the process from a safe distance.

- Consistent Quality: Automation reduces variability, ensuring safer and more reliable structural components.

6. Customization for Complex Designs

Modern construction projects often feature complex architectural designs that require intricate steelwork. CNC drilling machines can be programmed to execute complex drilling patterns, making it easier to fabricate components that fit unique design specifications.

Benefit:

- Supports Innovation: Enables the creation of customized steel elements for avant-garde architecture.

- Flexible Operations: Machines can quickly adapt to new designs without requiring extensive setup changes.

7. Durability and Longevity

Modern drilling machines are designed for heavy-duty operations and extended use. Machines like those from Trinkle Enterprise Co., Ltd. feature robust construction and durable components, ensuring they can withstand the demands of continuous steel fabrication.

Benefit:

- Reduced Downtime: Durable machines require less frequent maintenance, keeping operations running smoothly.

- Long-Term Investment: Reliable performance over years of service provides a high return on investment.

Conclusion

Drilling machines have fundamentally transformed steel fabrication in the construction industry. Their precision, automation, versatility, and efficiency make them indispensable tools for modern infrastructure projects. By reducing costs, improving safety, and enabling complex designs, these machines help construction companies meet the ever-growing demands of quality and speed.

Trinkle Enterprise Co., Ltd. is committed to providing state-of-the-art drilling machines that empower steel fabricators to achieve maximum productivity and precision. To learn more about our innovative drilling solutions and how they can benefit your construction projects, visit Trinkle Enterprise Co., Ltd..