News

News5 Key Benefits of Using CNC Gantry Drilling Machines in Modern Manufacturing

5 Key Benefits of Using CNC Gantry Drilling Machines in Modern Manufacturing

Introduction

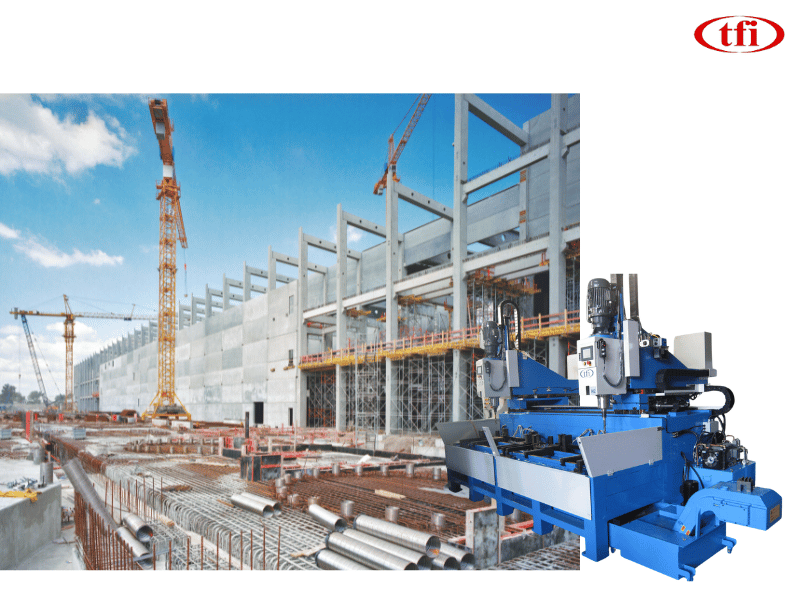

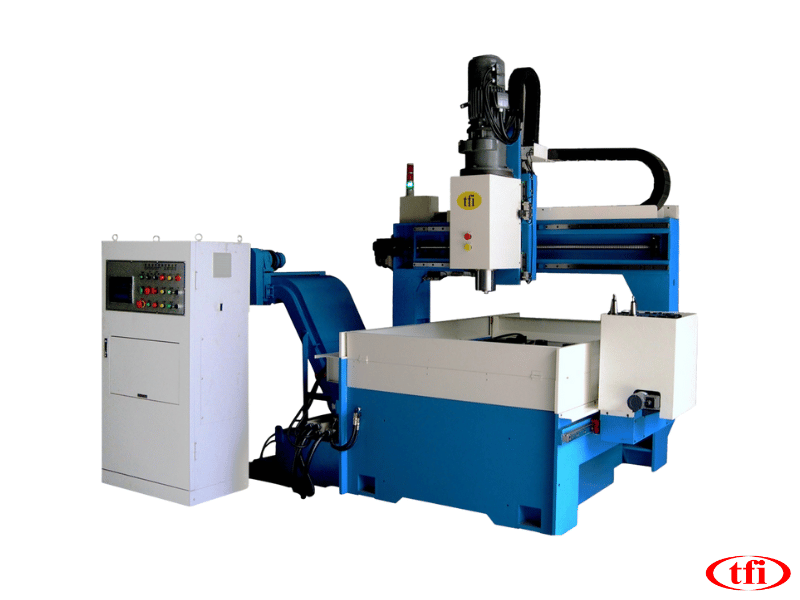

As the demand for precision, efficiency, and automation in modern manufacturing continues to rise, CNC Gantry Drilling Machines have become a crucial asset for industries that require high-precision drilling on large and heavy materials. These machines are particularly vital in sectors such as steel fabrication, construction, aerospace, and heavy machinery production, where high accuracy and productivity are essential.

Trinkle Enterprise Co., Ltd., a leading manufacturer of CNC drilling solutions, provides state-of-the-art CNC Gantry Drilling Machines that enhance efficiency, reduce costs, and improve manufacturing precision. In this article, we will explore the five key benefits of using CNC Gantry Drilling Machines and why they are indispensable in modern manufacturing.

________________________________________

1. Enhanced Precision and Accuracy

One of the primary advantages of CNC Gantry Drilling Machines is their ability to achieve extremely precise drilling results. Traditional manual drilling methods often suffer from alignment issues and human error, whereas CNC-controlled gantry drilling machines ensure that each hole is drilled with pinpoint accuracy.

Why It Matters:

- Consistent Hole Placement: CNC automation ensures that every hole is drilled in the exact position according to pre-programmed coordinates.

- Multi-Axis Control: The advanced CNC system allows the drilling head to move along multiple axes, enabling complex drilling patterns with minimal deviation.

- High Repeatability: Whether drilling a single workpiece or a large batch, CNC gantry drilling machines provide identical results every time, ensuring uniform quality.

Example:

Steel fabricators working on high-rise buildings or bridge components need precise bolt hole placements to ensure structural integrity. CNC gantry drilling machines eliminate the risk of misaligned holes, reducing rework and improving project quality.

________________________________________

2. Increased Productivity and Efficiency

CNC Gantry Drilling Machines drastically reduce production time compared to conventional drilling processes. With automated tool changes, multi-axis drilling, and high-speed operation, these machines can process large materials quickly and efficiently.

Key Productivity Features:

- Automatic Tool Changers (ATC): Reduces downtime by swiftly switching between different drill bits.

- Simultaneous Multi-Spindle Operations: Some CNC gantry drilling machines can operate multiple spindles at once, significantly increasing throughput.

- Batch Processing Capabilities: Large workpieces can be stacked and drilled simultaneously, maximizing production output.

Example:

In the wind energy sector, turbine tower flanges require multiple precisely drilled holes for bolting. CNC Gantry Drilling Machines allow manufacturers to drill multiple holes in one setup, drastically reducing lead time and enhancing productivity.

________________________________________

3. Versatility for a Wide Range of Applications

CNC Gantry Drilling Machines are highly adaptable and can be used for various drilling applications across multiple industries. Their ability to handle large, thick, and heavy workpieces makes them ideal for construction, shipbuilding, automotive, and aerospace applications.

Versatile Capabilities:

- Drilling, tapping, and countersinking in steel, aluminum, and composite materials.

- Suitable for processing I-beams, H-beams, plates, and welded components.

- Customizable CNC programming for unique drilling patterns and shapes.

Example:

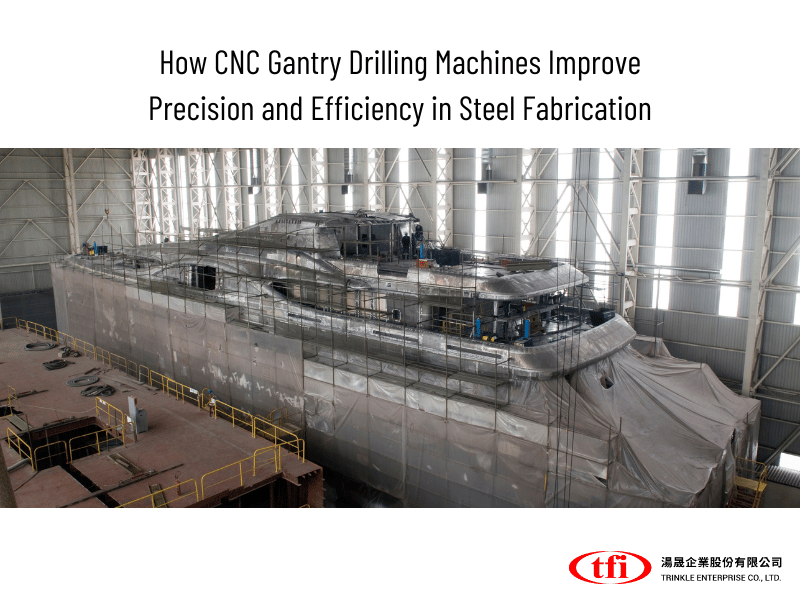

Shipbuilding requires large steel plates with precisely drilled holes for component assembly. CNC Gantry Drilling Machines allow manufacturers to customize drilling operations for different ship designs without requiring manual adjustments.

________________________________________

4. Cost Reduction Through Automation

Investing in CNC Gantry Drilling Machines leads to significant cost savings by minimizing labor costs, reducing material waste, and increasing operational efficiency.

How It Lowers Costs:

- Reduced Human Labor: Automated CNC operations minimize the need for manual intervention, cutting down on labor costs.

- Lower Error Rates: Precision drilling eliminates costly material waste caused by misaligned or incorrect holes.

- Energy Efficiency: Modern CNC machines are designed to optimize power consumption, reducing operational expenses.

Example:

A steel fabrication plant producing bridge components switched from manual drilling to CNC gantry drilling. The result? A 30% reduction in labor costs and a 50% increase in production efficiency, leading to higher profitability.

________________________________________

5. Improved Safety and Operator Convenience

Manufacturing environments involve heavy machinery, large materials, and complex drilling operations. CNC Gantry Drilling Machines prioritize safety by reducing direct human involvement in drilling tasks, minimizing workplace accidents.

Safety Features:

- Fully Automated Operations: Reduces the risk of accidents caused by manual drilling.

- Enclosed Work Areas & Protective Guards: Keeps operators safe from moving parts.

- User-Friendly CNC Interfaces: Modern machines feature intuitive touchscreens and programming tools, making them easier to operate with minimal training.

Example:

A construction equipment manufacturer implementing CNC drilling automation reported a 40% decrease in workplace accidents, proving the effectiveness of automated drilling in improving workplace safety.

________________________________________

Conclusion

CNC Gantry Drilling Machines have revolutionized the manufacturing industry by enhancing precision, efficiency, versatility, cost-effectiveness, and safety. These machines are essential for industries that require high-volume, high-accuracy drilling operations, such as construction, steel fabrication, aerospace, and shipbuilding.

Trinkle Enterprise Co., Ltd. is a trusted provider of advanced CNC Gantry Drilling Machines designed to meet the evolving demands of modern manufacturing. Our machines are built for maximum efficiency and durability, ensuring that your operations stay ahead of the competition.

To learn more about how our CNC Gantry Drilling Machines can transform your manufacturing process, visit Trinkle Enterprise Co., Ltd. today.