News

NewsHow CNC Gantry Drilling Machines Improve Precision and Efficiency in Steel Fabrication

How CNC Gantry Drilling Machines Improve Precision and Efficiency in Steel Fabrication

Introduction

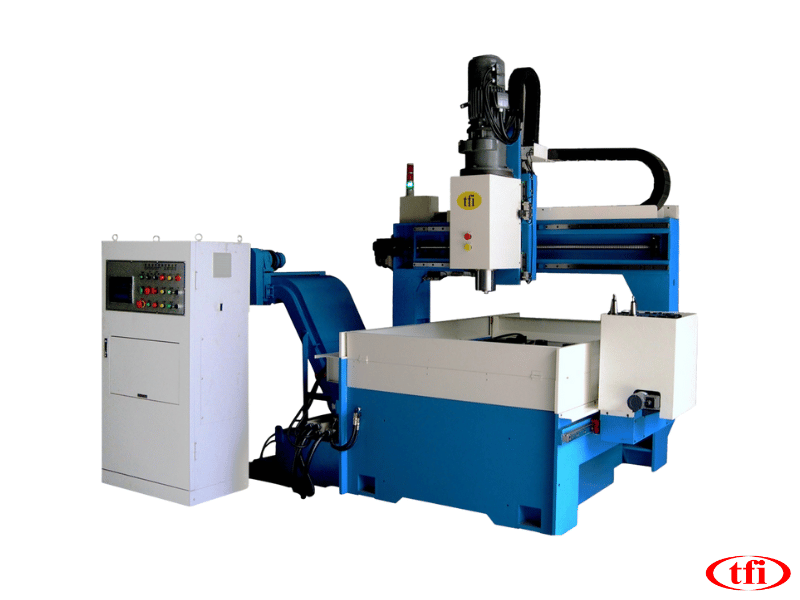

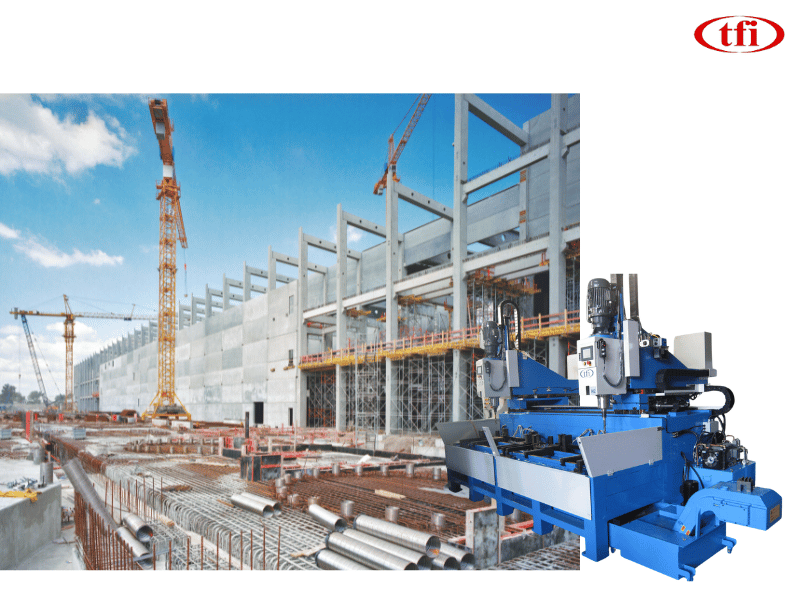

Steel fabrication is a critical process in industries such as construction, shipbuilding, and heavy machinery manufacturing. Precision and efficiency are essential to ensure the structural integrity of steel components while maintaining high production output. CNC Gantry Drilling Machines have transformed steel fabrication by offering unparalleled accuracy, automation, and productivity.

Trinkle Enterprise Co., Ltd., a leading provider of CNC drilling solutions, specializes in advanced CNC Gantry Drilling Machines that enhance the efficiency of steel fabrication processes. In this article, we explore how these machines improve precision and streamline operations in the steel fabrication industry.

________________________________________

1. Advanced CNC Technology for Unmatched Precision

One of the biggest advantages of CNC Gantry Drilling Machines is their ability to achieve exceptional drilling accuracy. Traditional manual drilling methods often result in slight misalignments, which can compromise the integrity of steel structures. CNC automation eliminates such errors by precisely controlling every drilling movement.

How It Improves Precision:

- Computer-Controlled Drilling: CNC technology ensures each hole is positioned accurately according to pre-programmed measurements.

- Multi-Axis Drilling: These machines allow precise hole placement on large steel plates, beams, and welded structures.

- Consistent Repeatability: Every workpiece receives the same level of precision, reducing deviations and rework.

Example:

In bridge construction, steel beams require precise hole placements for bolted connections. Using CNC Gantry Drilling Machines, fabricators can ensure that each hole is perfectly aligned, reducing assembly errors and ensuring the structural strength of the bridge.

________________________________________

2. Increased Efficiency with Automated Operations

Traditional steel fabrication methods involve manual positioning, drilling, and adjustments, leading to slower production rates. CNC Gantry Drilling Machines automate these processes, significantly increasing efficiency and reducing labor requirements.

Efficiency-Boosting Features:

- Automated Drilling Programs: Operators can program multiple hole patterns and drilling sequences, eliminating manual intervention.

- Multi-Spindle Drilling: Some machines can drill multiple holes simultaneously, cutting production time by half.

- Batch Processing: Large steel sheets or stacked plates can be processed in a single setup, enhancing throughput.

Example:

A steel fabrication company manufacturing wind turbine bases switched from manual drilling to CNC automation. As a result, they doubled their production speed, completing projects in half the time while maintaining high precision.

________________________________________

3. High Versatility for Complex Steel Structures

Modern steel fabrication requires the ability to handle a wide range of components, from H-beams and I-beams to large metal plates. CNC Gantry Drilling Machines are versatile enough to process various materials and sizes.

Versatility Advantages:

- Handles Heavy-Duty Materials: Can drill through thick steel plates and beams with ease.

- Adapts to Different Fabrication Needs: Used for bridges, high-rise buildings, industrial plants, and more.

- Supports Custom Drilling Patterns: Enables drilling of complex hole arrangements for unique designs.

Example:

A shipyard needed to drill thousands of holes in large steel panels for a new vessel design. By implementing a CNC Gantry Drilling Machine, they eliminated misalignment issues and increased daily output, reducing production delays.

________________________________________

4. Cost Reduction Through Process Optimization

Investing in CNC Gantry Drilling Machines leads to substantial cost savings by reducing material waste, minimizing labor costs, and improving operational efficiency.

How It Lowers Costs:

- Reduces Material Waste: Precision drilling ensures correct hole placement, avoiding scrap materials.

- Minimizes Labor Requirements: Automation reduces the need for multiple workers, cutting labor costs.

- Energy-Efficient Design: Modern CNC machines optimize power usage, leading to lower electricity bills.

Example:

A construction company specializing in pre-fabricated steel structures reduced its operational costs by 40% after switching to CNC drilling automation, thanks to faster production times and fewer material losses.

________________________________________

5. Enhanced Safety and Operator Convenience

Steel fabrication involves large, heavy materials, making workplace safety a top priority. CNC Gantry Drilling Machines reduce direct human involvement, lowering the risk of workplace injuries.

Safety Features:

- Fully Enclosed Workspaces: Protects operators from moving parts and flying debris.

- Automated Spindle Movement: Reduces the need for manual tool adjustments, preventing accidents.

- User-Friendly Interface: Simple CNC controls allow easy programming, even for less experienced operators.

Example:

A steel processing facility reported a 50% drop in workplace accidents after replacing manual drilling operations with CNC Gantry Drilling Machines.

Q1: How do CNC Gantry Drilling Machines improve precision in steel fabrication?

✅ Answer:

CNC Gantry Drilling Machines improve precision by using computer-controlled automation to ensure exact hole placement, multi-axis drilling capabilities, and repeatable accuracy. This eliminates human error and ensures that every hole meets precise specifications, which is crucial for bolted and welded steel structures.

________________________________________

Q2: What industries benefit the most from CNC Gantry Drilling Machines?

✅ Answer:

Industries that benefit the most include:

• Construction & Steel Fabrication (for high-rise buildings, bridges, and industrial plants)

• Shipbuilding (for drilling large steel panels and hull structures)

• Heavy Machinery Manufacturing (for precise component assembly)

• Energy Sector (for wind turbine towers, oil platforms, and infrastructure)

• Aerospace & Automotive (for high-precision metal components)

________________________________________

Q3: How do CNC Gantry Drilling Machines increase efficiency compared to manual drilling?

✅ Answer:

• Automated multi-axis drilling reduces the need for manual adjustments.

• Batch processing allows multiple steel plates or beams to be drilled in a single setup.

• Automatic tool changers (ATC) speed up the process by switching drill bits quickly.

• Pre-programmed CNC operations allow for continuous drilling without operator intervention.

• Multi-spindle capability enables simultaneous drilling, further increasing productivity.

________________________________________

Q4: What cost-saving benefits do CNC Gantry Drilling Machines provide?

✅ Answer:

• Lower labor costs by reducing manual operation.

• Minimized material waste due to precision drilling and reduced errors.

• Increased tool lifespan with optimized spindle feeding and cutting speeds.

• Higher energy efficiency, reducing electricity consumption.

• Faster production times, reducing overall project costs.

________________________________________

Q5: Why should a steel fabrication company invest in a CNC Gantry Drilling Machine?

✅ Answer:

Investing in a CNC Gantry Drilling Machine enhances manufacturing speed, accuracy, and cost-efficiency. It ensures that steel components are drilled with high precision, improves workplace safety, and reduces production bottlenecks. This results in higher-quality output, increased productivity, and greater profitability—making it a smart investment for modern steel fabrication companies.

Conclusion

CNC Gantry Drilling Machines have revolutionized steel fabrication, offering superior precision, automation, and efficiency. These machines have become indispensable for industries requiring high-volume, high-accuracy drilling in steel components.

Key Takeaways:

✅ Increased Precision: Eliminates human error in drilling operations.

✅ Higher Productivity: Automates drilling sequences for faster output.

✅ Versatile Applications: Handles beams, plates, and customized structures.

✅ Cost-Effective: Reduces labor and material waste.

✅ Safer Work Environment: Minimizes direct operator involvement in drilling.

As a trusted provider of CNC drilling solutions, Trinkle Enterprise Co., Ltd. offers state-of-the-art CNC Gantry Drilling Machines designed to enhance steel fabrication processes. For more information, visit Trinkle Enterprise Co., Ltd..