News

NewsTop 3 Industrial Applications of Modern Drilling Machines

Top 3 Industrial Applications of Modern Drilling Machines

Introduction

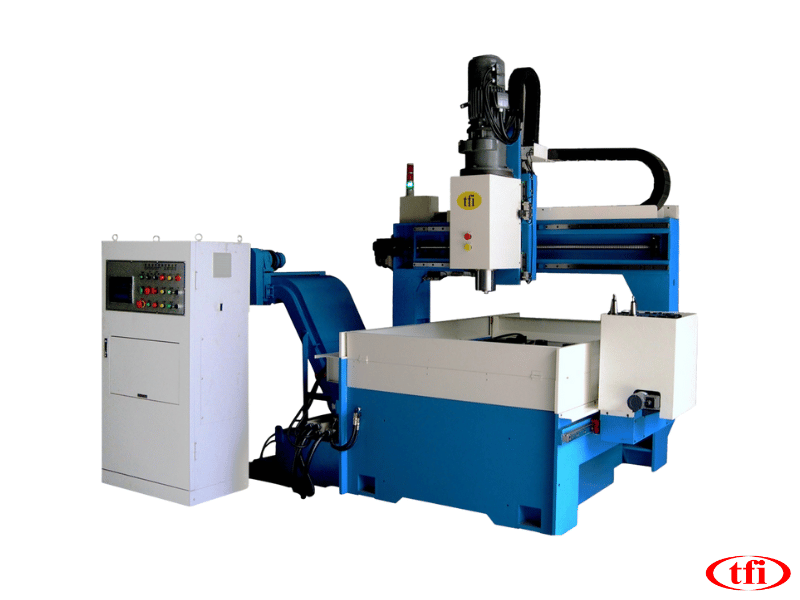

Drilling machines have long been a fundamental part of industrial manufacturing. However, with technological advancements, modern drilling machines have become more versatile, efficient, and precise, making them indispensable in various industries. From small-scale workshops to large-scale manufacturing plants, drilling machines play a critical role in processing materials for different applications. Trinkle Enterprise Co., Ltd., a leader in drilling machine technology, offers cutting-edge solutions that cater to a wide range of industries. This article will explore the top three industrial applications of modern drilling machines, highlighting their importance in construction, aerospace, and automotive sectors.

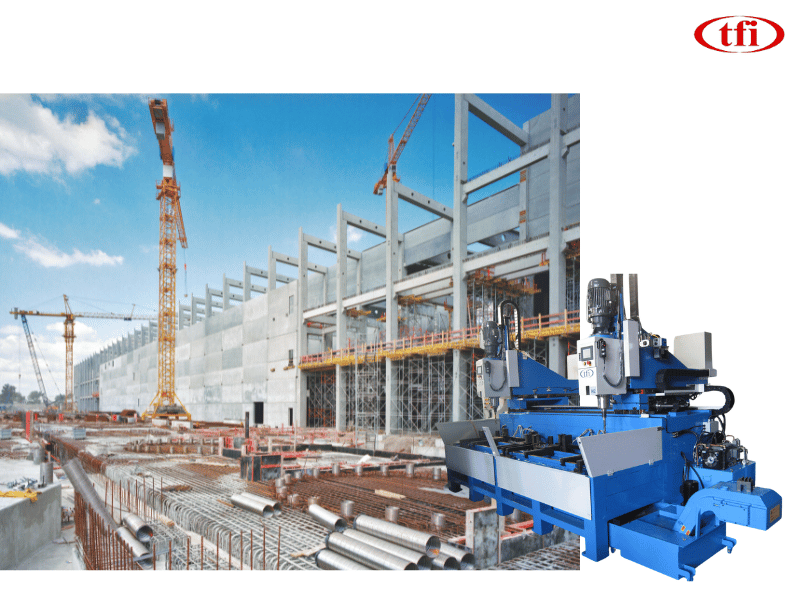

1. Construction and Structural Fabrication

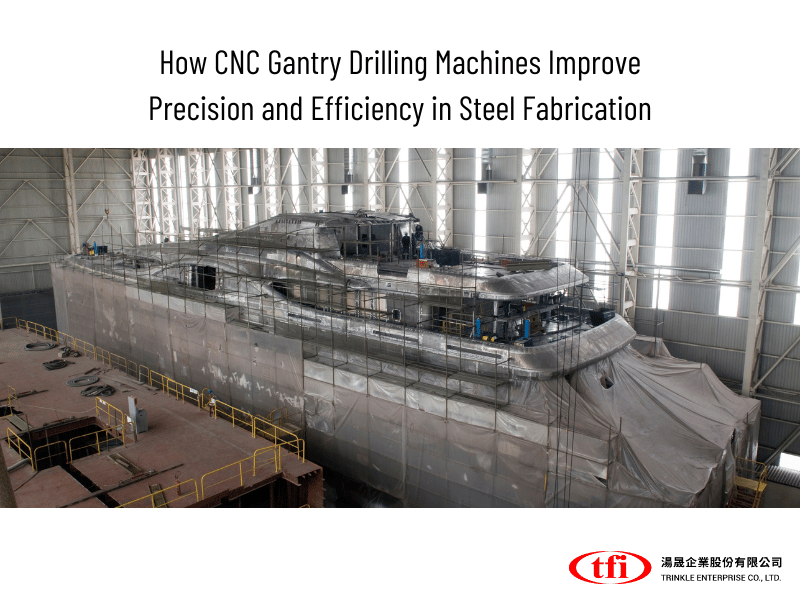

Precision in Steel Frameworks

One of the most prominent applications of modern drilling machines is in the construction industry, particularly in steel fabrication. Large infrastructure projects such as bridges, high-rise buildings, and industrial plants require robust steel frameworks, where every beam and plate must be drilled with precision for bolting and riveting. Modern CNC-controlled drilling machines from Trinkle Enterprise Co., Ltd. ensure that holes are drilled accurately, reducing errors and improving the overall strength of the structure.

Benefits in Construction

- Time Efficiency: Automated drilling machines allow for faster processing, helping construction projects adhere to tight timelines.

- Reduced Labor Costs: With advanced drilling technology, fewer manual adjustments are needed, reducing labor hours and associated costs.

- High-Volume Production: Modern drilling machines are designed to handle large batches of steel plates and beams, making them ideal for mass production in large-scale construction projects.

Example: Skyscraper Construction

In skyscraper construction, drilling machines are used to create the framework that supports the entire structure. Steel beams need precise drilling for bolting, ensuring the stability and safety of the building. Without modern drilling machines, this process would be much slower and less accurate, risking structural integrity.

2. Aerospace Manufacturing

Lightweight and High-Strength Components

The aerospace industry relies on drilling machines to produce parts that meet strict safety and performance standards. Aerospace components, such as aircraft wings, fuselages, and engine parts, are made from lightweight materials like aluminum and titanium, which require precise drilling without compromising their strength. Modern drilling machines equipped with CNC technology from Trinkle Enterprise Co., Ltd. ensure that every hole is drilled to exact specifications, contributing to the overall safety and efficiency of the aircraft.

Benefits in Aerospace

- Precision and Accuracy: The aerospace industry demands extremely tight tolerances, and CNC drilling machines offer the precision needed to meet these stringent requirements.

- Material Efficiency: With modern drilling machines, manufacturers can minimize material waste by optimizing the drilling process for lightweight materials.

- Consistency: Automated drilling machines provide consistent results, ensuring that each component meets the same quality standards.

Example: Aircraft Component Fabrication

In the production of aircraft wings and fuselages, drilling machines are used to create precise holes for fasteners and rivets. These holes must be drilled without causing cracks or stress points in the materials. Modern drilling machines ensure that each hole is drilled with the same level of precision, reducing the risk of component failure during flight.

3. Automotive Industry

Mass Production of Vehicle Parts

The automotive industry is another key sector that relies heavily on modern drilling machines. Vehicle manufacturing involves the mass production of various components, from engine blocks to suspension parts, each requiring precise drilling for assembly. Modern drilling machines, particularly those equipped with robotic automation, allow automotive manufacturers to meet high production demands while maintaining accuracy and consistency. Trinkle Enterprise Co., Ltd. offers high-performance drilling solutions tailored for the automotive industry.

Benefits in Automotive Manufacturing

- Increased Production Speed: Modern drilling machines can handle the fast-paced demands of automotive manufacturing, producing high volumes of parts in a short amount of time.

- Cost-Effective: Automated drilling reduces the need for manual labor, cutting down on production costs while maintaining product quality.

- Customizable Operations: Modern CNC drilling machines can be programmed to handle different materials and designs, allowing manufacturers to produce various vehicle components with ease.

Example: Engine Block Manufacturing

In engine block production, drilling machines are used to create holes for pistons, valves, and other essential components. These holes must be perfectly aligned to ensure the engine functions efficiently. Modern drilling machines, with their programmable features, enable manufacturers to produce high-quality engine blocks at scale while maintaining precision.

Conclusion

Modern drilling machines have revolutionized multiple industries, playing an essential role in ensuring precision, efficiency, and high-volume production. In the construction, aerospace, and automotive sectors, these machines are indispensable tools that enhance productivity and quality. Trinkle Enterprise Co., Ltd., a leader in modern drilling technology, offers state-of-the-art solutions that cater to the diverse needs of these industries. As technology continues to advance, drilling machines will likely become even more efficient, further solidifying their importance across a wide range of industrial applications.

For manufacturers looking to improve precision and efficiency in their operations, Trinkle Enterprise Co., Ltd. provides the perfect drilling solutions designed to meet your unique needs.