News

NewsThe Versatile Applications of Gantry-Type Plate Drilling Machines in Construction

The Versatile Applications of Gantry-Type Plate Drilling Machines in Construction

Introduction

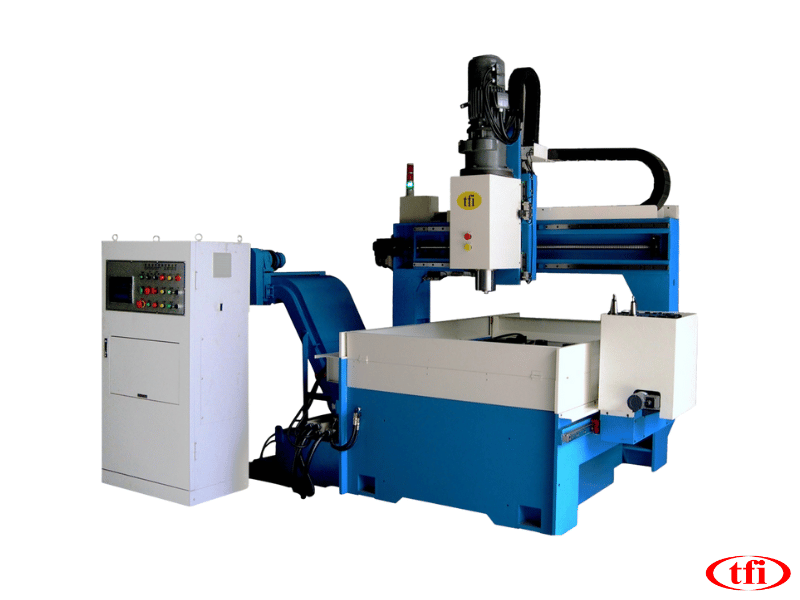

Gantry-type plate drilling machines are renowned for their precision, versatility, and efficiency in processing large metal plates. These machines have become indispensable in various industries due to their ability to handle heavy-duty drilling tasks with unmatched accuracy. For manufacturers in the construction industry, the integration of gantry-type plate drilling machines can significantly enhance productivity and ensure the structural integrity of projects. This article explores the broad applications of these machines, with a particular focus on their role in construction and structural engineering.

Applications of Gantry-Type Plate Drilling Machines

Gantry-type plate drilling machines are widely used across multiple industries, including:

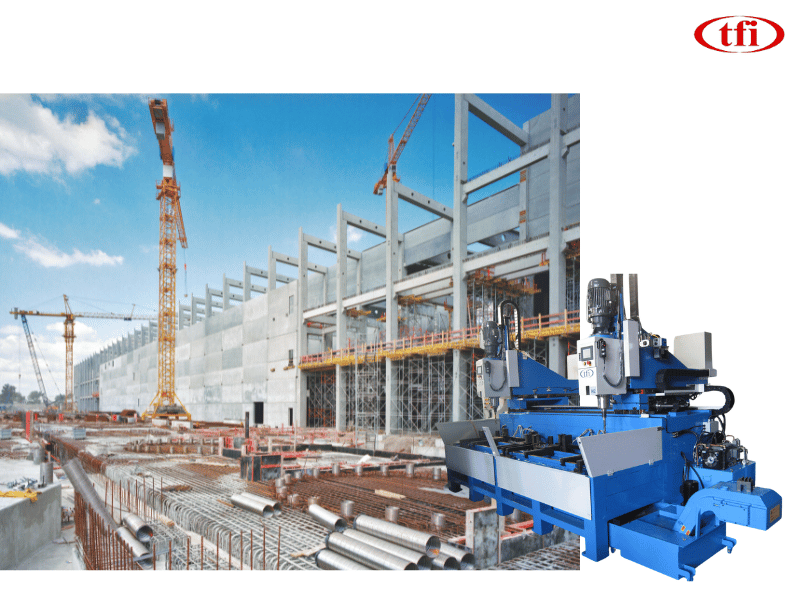

- Construction and Structural Engineering: Essential for fabricating steel frameworks and other structural components.

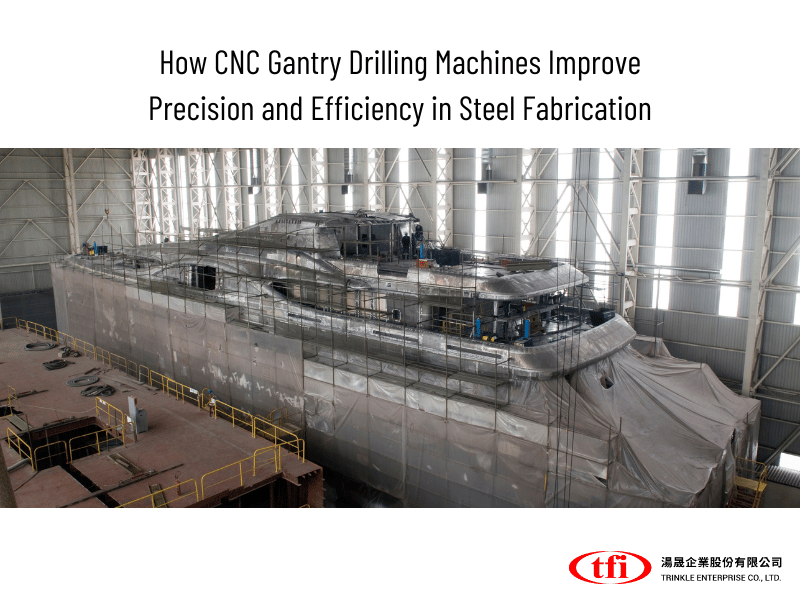

- Shipbuilding: Used for assembling large ships, where precision drilling in beams and plates is critical.

- Heavy Machinery Manufacturing: Vital for producing robust structural components for cranes, excavators, and other heavy equipment.

- Aerospace and Automotive: Utilized for high-precision drilling in large plates and structural parts.

- Energy Sector: Employed in fabricating wind turbine components, oil platforms, and other energy infrastructure.

- Bridge Construction: Crucial for drilling large beams and plates used in bridge frameworks.

Spotlight on Construction and Structural Engineering

-

The Importance of Gantry-Type Plate Drilling Machines in Construction

In the construction and structural engineering sectors, the demand for precision and efficiency is paramount. Gantry-type plate drilling machines play a crucial role in meeting these demands by facilitating the accurate drilling of large steel plates and beams, which are fundamental to the structural integrity of buildings, bridges, and other infrastructure projects.

-

Enhancing Structural Integrity

One of the most critical applications of gantry-type plate drilling machines in construction is the fabrication of steel frameworks. These machines ensure that every hole drilled for bolts, rivets, and other fasteners is precise, allowing for tight, secure connections that contribute to the overall stability and safety of the structure. This precision is particularly important in high-rise buildings and complex architectural designs, where even minor deviations can have significant impacts on structural integrity.

-

Improving Efficiency and Reducing Costs

Gantry-type plate drilling machines are designed to handle large and heavy workpieces, making them ideal for processing the thick steel plates commonly used in construction. By automating the drilling process, these machines not only improve precision but also significantly reduce manual labor and associated costs. This automation enables construction companies to accelerate their production timelines, reduce errors, and ultimately lower overall project costs.

Versatility in Application

The versatility of gantry-type plate drilling machines allows them to be used for a wide range of construction-related tasks. Whether it’s drilling precise holes in steel beams for a building's skeleton or processing the large metal plates used in infrastructure projects, these machines can adapt to various materials and project requirements. This adaptability makes them an invaluable asset in a construction manufacturer’s toolkit.

Case Study: Steel Fabrication for Skyscrapers

In skyscraper construction, steel frameworks are the backbone of the entire structure. The beams and plates used in these frameworks must be drilled with extreme precision to ensure they fit together perfectly during assembly. Gantry-type plate drilling machines from manufacturers like Trinkle Enterprise Co., Ltd. offer the precision and efficiency needed for these demanding applications. By utilizing advanced CNC technology, these machines can drill multiple holes with exact specifications, reducing the need for rework and ensuring that all components meet the stringent safety and quality standards required in high-rise construction.

Supporting Sustainable Construction Practices

Gantry-type plate drilling machines also support sustainable construction practices. By optimizing the drilling process, these machines help minimize material waste and energy consumption. The precision of these machines ensures that materials are used efficiently, which aligns with the construction industry’s increasing focus on sustainability and resource conservation.

Conclusion

For manufacturers in the construction industry, the integration of gantry-type plate drilling machines is a strategic investment that enhances precision, efficiency, and overall project quality. These machines are not just tools but vital components that enable construction companies to meet the high standards of modern building projects.

With their versatility and advanced features, gantry-type plate drilling machines, like those offered by Trinkle Enterprise Co., Ltd., are poised to become essential assets in the quest for excellence in construction and structural engineering.

For more information on advanced gantry-type plate drilling solutions, visit Trinkle Enterprise Co., Ltd..