News

NewsCNC Single Gantry Drilling Machine DNC-1635H

CNC Single Gantry Drilling Machine DNC-1635H

Introduction

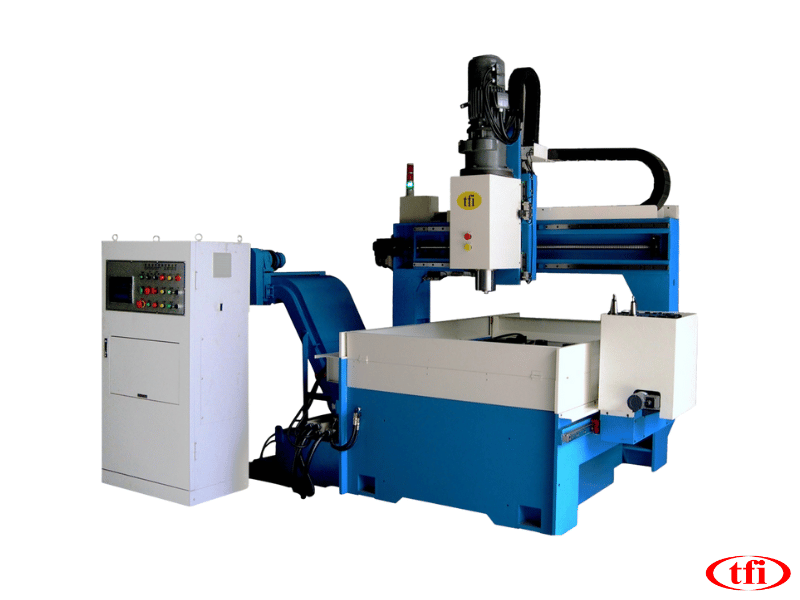

In today's fast-paced manufacturing environment, precision and efficiency are critical to staying competitive. The DNC-1635H CNC Plate Drilling Machine by Trinkle Enterprise Co., Ltd. represents a significant advancement in drilling technology, combining innovative features with robust design to meet the demanding needs of modern industries. This article explores the key attributes of the DNC-1635H and its applications, showcasing why it stands out in the market.

Overview of the DNC-1635H

The DNC-1635H is part of the DNC series, known for its single gantry type configuration, which ensures stability and precision during drilling operations. This series can accommodate large workpieces, with a maximum size of 1.6 meters in length (X-axis) and 3.5 meters in width (Y-axis). The machine is equipped with a hydraulic feeding spindle, providing reliable and consistent performance.

Key Features

- Independent Hydraulic Cylinder Design: The DNC-1635H's spindle utilizes an independent hydraulic cylinder design, which simplifies maintenance and enhances durability. This feature ensures that any required servicing can be conducted quickly and efficiently, minimizing downtime.

- Advanced Feeding Control: The integration of an encoder allows the hydraulic feeding system to closely mimic the precision of servo-controlled feeding. This near-servo functionality enables full-automatic feeding management, optimizing the cutting process for maximum efficiency.

- Thickness-Measuring Encoder: The DNC-1635H is equipped with a thickness-measuring encoder that precisely controls the cutting position and adjusts the cutting mode—heavy-cutting, light-cutting, and blank-cutting—based on the material thickness. This results in superior cutting efficiency and accuracy.

- BT-40 Quick-Change Shank: The machine features a BT-40 Quick-Change Shank, which significantly reduces tool change time. With just the press of a button, bits can be loaded and removed in one second. This system is cost-effective, with a price one-third that of traditional straight shanks, yet it increases tool deflection tenfold, enhancing overall performance.

- Patent Tool Length and Workpiece Thickness Measuring Device: The patented tool length and workpiece thickness measuring device allow the DNC-1635H to achieve full-automatic feeding management. This innovation eliminates the need for manual adjustments of limit switches, saving valuable working hours and ensuring consistent quality.

Benefits

- Enhanced Efficiency: The advanced hydraulic feeding system and automatic management features significantly reduce cycle times and increase productivity.

- High Precision: Encoders and measuring devices ensure precise control over cutting positions and tool management, leading to superior quality.

- Cost-Effective Operation: The BT-40 Quick-Change Shank and efficient hydraulic system offer substantial cost savings compared to traditional methods.

- Ease of Maintenance: The independent hydraulic cylinder design simplifies maintenance procedures, reducing downtime and operational disruptions.

Applications

The DNC-1635H is designed to meet the diverse needs of various industries, including:

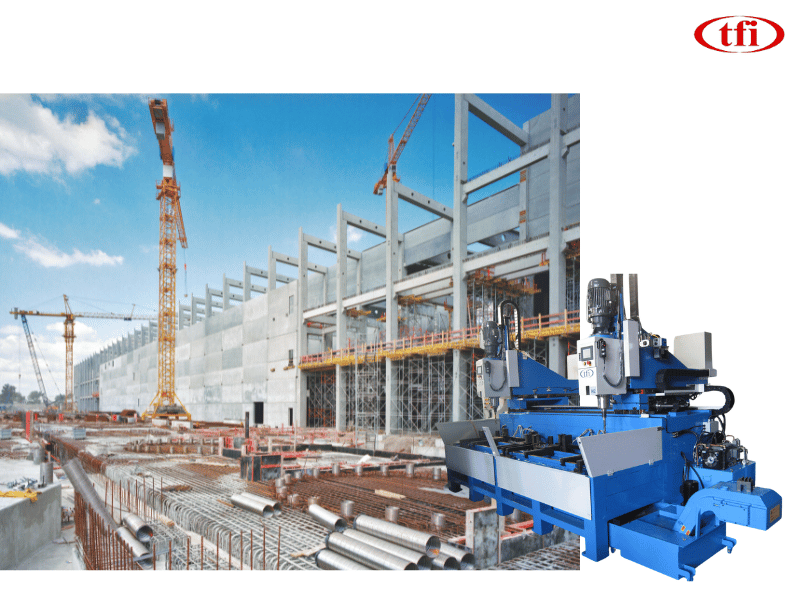

- Construction: In the construction industry, the DNC-1635H is ideal for fabricating large steel plates used in building frameworks and infrastructure projects. Its ability to handle large workpieces and provide precise drilling ensures structural integrity and speeds up the construction process.

- Heavy Machinery Manufacturing: Manufacturers of heavy machinery, such as cranes, excavators, and bulldozers, benefit from the DNC-1635H’s precision and efficiency. The machine’s advanced features enable the production of robust structural components, critical for the performance and safety of heavy equipment.

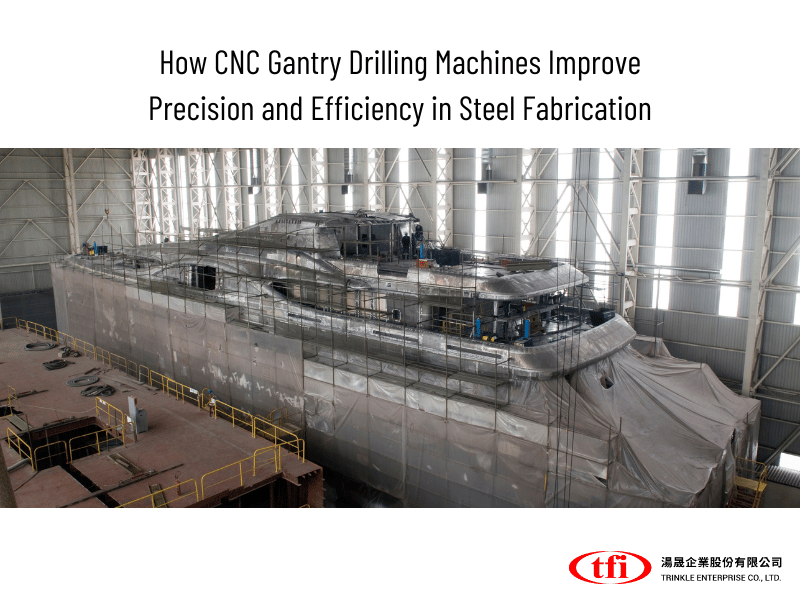

- Shipbuilding: The shipbuilding industry requires high precision in the drilling of large metal plates that form the hull and main body of vessels. The DNC-1635H ensures accurate hole placement, contributing to the overall strength and durability of ships.

- Aerospace and Automotive Industries: In aerospace and automotive manufacturing, the DNC-1635H provides the precision needed for critical components. Its advanced control systems and high efficiency make it suitable for producing parts that meet stringent industry standards.

Conclusion

The DNC-1635H CNC Plate Drilling Machine by Trinkle Enterprise Co., Ltd. is a game-changer in the field of industrial drilling. With its innovative features, including independent hydraulic cylinder design, advanced feeding control, and quick-change shank system, it offers unparalleled precision, efficiency, and cost-effectiveness. This machine is poised to meet the demands of various industries, providing reliable performance and superior quality.

For more information on the DNC-1635H and other advanced drilling solutions, visit Trinkle Enterprise Co., Ltd.