News

NewsDrilling Machine Applications: A Comprehensive Guide

Drilling Machine Applications: A Comprehensive Guide

Introduction

Drilling machines, integral components of the manufacturing industry, serve the critical function of creating precise holes in a range of materials. From simple manual drills to advanced CNC drilling machines, the evolution of this technology reflects the growing complexity and precision required in industrial operations. Trinkle Enterprise Co., Ltd., a leader in the production of advanced drilling solutions, offers a wide array of machines designed to meet the diverse needs of today’s industries.

Key Applications of Drilling Machines

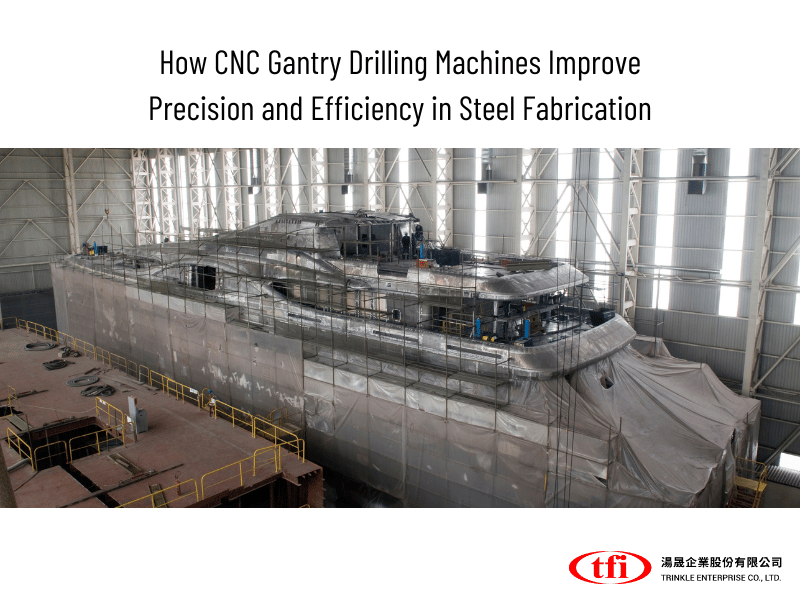

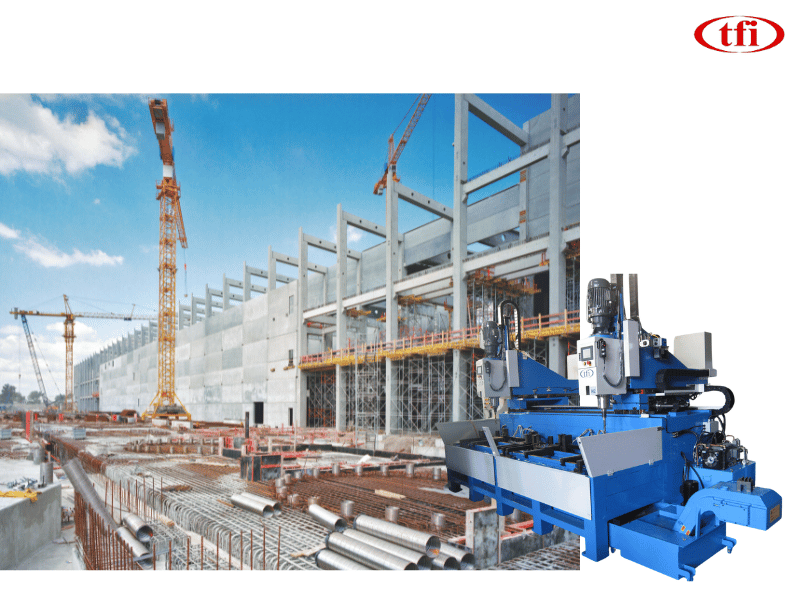

Construction and Infrastructure

In the construction sector, drilling machines are used to create foundations, prepare sites for explosives, and install fixtures and utilities. Heavy-duty drills, such as rotary drills and hammer drills, penetrate through concrete and masonry, facilitating the erection of buildings, bridges, and roads.

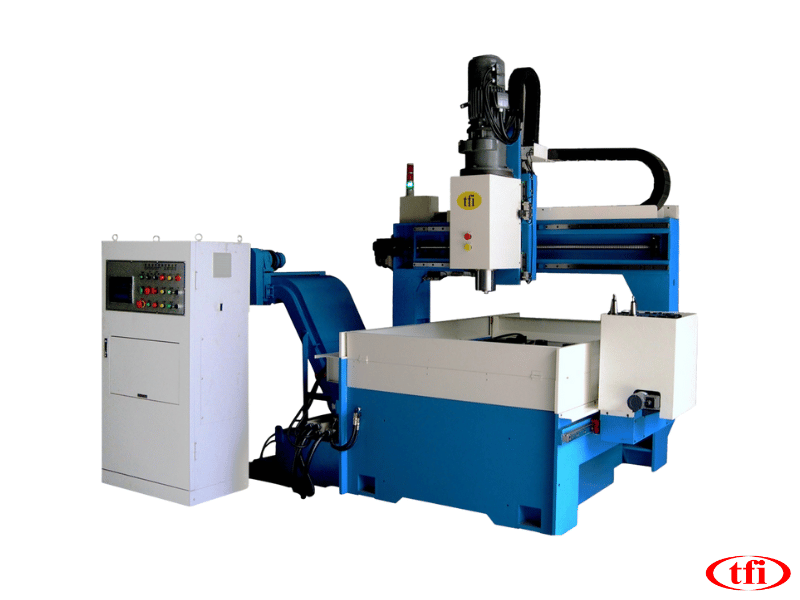

Metal Fabrication

Metal fabrication relies heavily on drilling machines to produce components with high precision. CNC drilling machines, offered by Trinkle Enterprise, play a pivotal role in this sector, allowing for the automated drilling of holes with exact dimensions and tolerances, critical for the aerospace, automotive, and defense industries.

Oil and Gas Exploration

The oil and gas industry utilizes specialized drilling machines capable of penetrating deep into the earth's crust. These machines, including rotary table drills and top drive systems, are essential for exploring and extracting natural resources.

Woodworking and Carpentry

In woodworking, drilling machines are used for creating joints, installing hardware, and preparing pieces for assembly. Trinkle Enterprise provides a range of drills that cater to the precision and delicacy required in woodworking, from crafting furniture to constructing wooden structures.

Electronics and Technology

Precision drilling machines are crucial in the electronics industry for creating circuit boards and assembling electronic components. Trinkle’s high-precision CNC drilling machines ensure the accurate placement of components, essential for the functionality of electronic devices.

Medical Device Manufacturing

The production of medical devices requires extreme precision, where even a minor deviation can render a device ineffective or unsafe. Drilling machines are used to create precise holes and cavities in medical implants, surgical instruments, and diagnostic equipment.

Innovations in Drilling Machine Technology

Trinkle Enterprise Co., Ltd. is at the forefront of drilling machine technology, constantly innovating to provide machines that offer greater accuracy, efficiency, and versatility. The company's commitment to research and development has led to the introduction of machines with enhanced capabilities, such as multi-axis CNC drilling machines, which can perform complex drilling operations in a single setup.

Choosing the Right Drilling Machine

Selecting the appropriate drilling machine depends on several factors, including the material to be drilled, the precision required, and the volume of production. Trinkle Enterprise’s experts work closely with clients to understand their needs and recommend the best solutions, ensuring optimal performance and productivity.

Conclusion

Drilling machines are vital to the operations of numerous industries, offering the ability to create precise holes in a variety of materials and applications. Trinkle Enterprise Co., Ltd., with its wide range of drilling solutions and commitment to innovation, plays a critical role in supporting the diverse needs of modern manufacturing. As industries continue to evolve, the demand for more advanced and specialized drilling machines will grow, and Trinkle Enterprise is poised to meet this challenge head-on, pushing the boundaries of what is possible in drilling technology.