News

NewsHow to Maintain Accuracy and Avoid Failures in the Use of CNC Plate Drilling Machines

How to Maintain Accuracy and Avoid Failures in the Use of CNC Plate Drilling Machines

Introduction

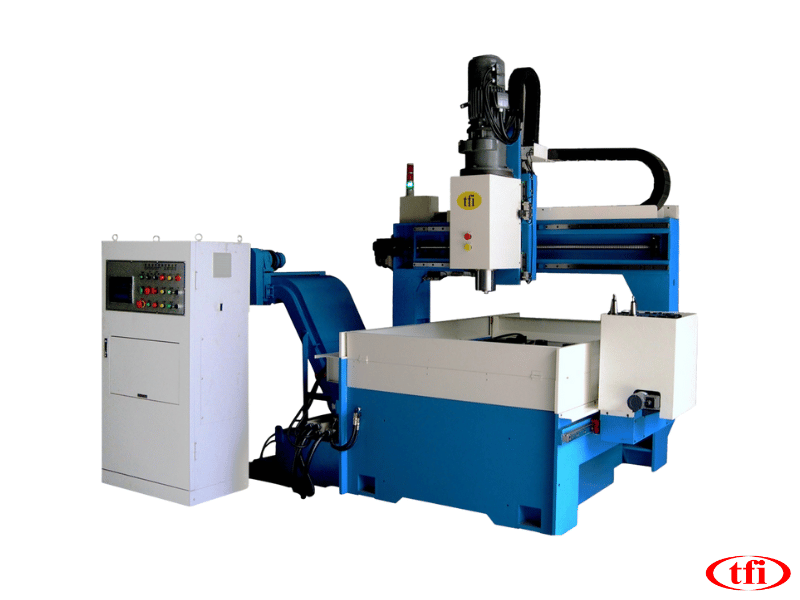

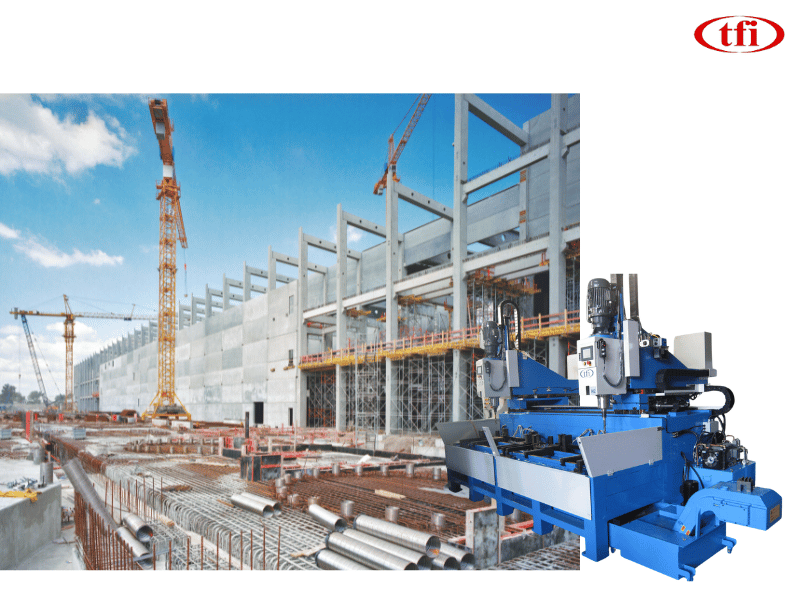

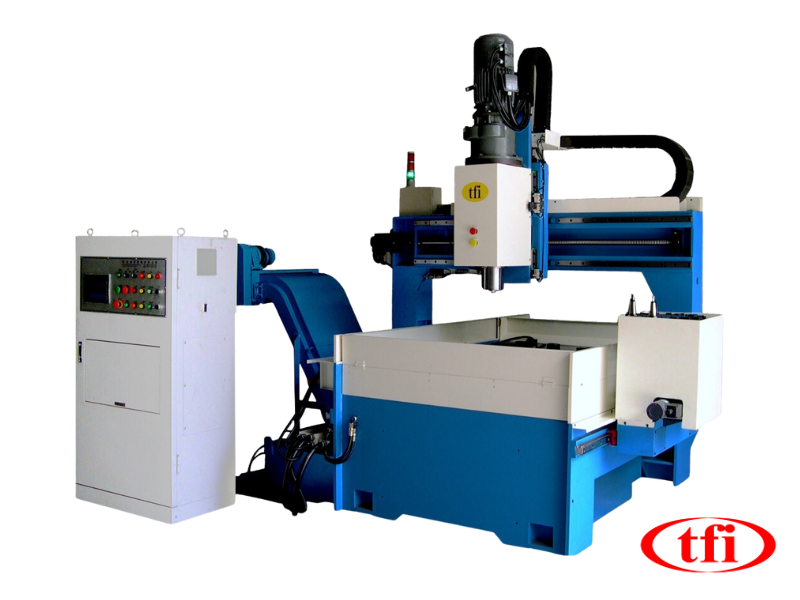

In the precision-demanding world of metal fabrication, CNC Plate Drilling Machines stand out for their ability to deliver high accuracy and efficiency. These machines, designed to automate complex drilling operations on large metal plates, are pivotal in industries ranging from construction to aerospace. As a leading provider of these innovative solutions, Trinkle Enterprise Co., Ltd. understands the importance of maintaining these machines to ensure they operate at their peak performance. This article offers a comprehensive guide on keeping your CNC Plate Drilling Machine accurate and reliable, minimizing downtime and maximizing productivity.

Understanding CNC Plate Drilling Machines

Before diving into maintenance and troubleshooting, it's crucial to understand what makes CNC Plate Drilling Machines indispensable. These machines offer unparalleled precision in drilling holes of various sizes and depths in metal plates, thanks to their computer numerical control (CNC) systems. They can handle various materials, including steel, aluminum, and composites, making them versatile tools in the manufacturing process.

Regular Maintenance: The Key to Accuracy and Longevity

Daily Checks

- Lubrication: Ensure all moving parts are well-lubricated to reduce friction and wear.

- Cleanliness: Keep the machine and its components clean from metal shavings and debris, which can affect accuracy and cause mechanical failures.

Weekly Inspections

- Check for Wear and Tear: Inspect tools and components for signs of wear, including drill bits and spindles. Early detection can prevent accuracy loss.

- Verify Software Updates: Keep the CNC software updated to ensure optimal performance and access to the latest features and bug fixes.

Monthly Calibrations

- Alignment Checks: Regularly check and calibrate the alignment of the drilling spindle to ensure precise hole locations.

- Tool Calibration: Ensure that all drilling tools are correctly calibrated and positioned to maintain drilling accuracy.

Avoiding Failures: Proactive Strategies

Understand Your Machine's Capabilities

Pushing your CNC Plate Drilling Machine beyond its limits can lead to premature wear or failure. Familiarize yourself with the machine's specifications and capabilities as provided by Trinkle Enterprise Co., Ltd., and adhere to recommended operating conditions.

Use High-Quality Tools and Materials

The quality of drill bits and other tools significantly impacts the machine's performance and the final product's quality. Investing in high-quality tools not only enhances accuracy but also extends the machine's lifespan.

Implement a Predictive Maintenance Program

Leveraging data from the CNC system can help predict potential failures before they occur. Monitoring vibration, temperature, and other machine parameters can provide early warnings of issues, allowing for preemptive maintenance.

Troubleshooting Common Issues

Inaccurate Drilling Results

- Cause: Wear and tear on drill bits, misalignment, or incorrect tool calibration.

- Solution: Regularly inspect and replace drill bits, realign the machine, and recalibrate tools as necessary.

Machine Downtime

- Cause: Mechanical failures, software glitches, or power issues.

- Solution: Conduct regular inspections, ensure reliable power supply, and keep software up to date.

Excessive Tool Wear

- Cause: Using incorrect drill speeds, feeds, or inadequate lubrication.

- Solution: Adjust drilling parameters according to material specifications and ensure proper lubrication.

Leveraging Expert Support from Trinkle Enterprise Co., Ltd.

While adhering to maintenance schedules and operational best practices is crucial, partnering with your CNC Plate Drilling Machine manufacturer, Trinkle Enterprise Co., Ltd., can provide additional support and resources. Trinkle's expert team offers comprehensive training, technical support, and maintenance services to ensure your machine's longevity and performance.

Conclusion

Maintaining accuracy and avoiding failures in the use of CNC Plate Drilling Machines require a comprehensive approach that includes regular maintenance, understanding the machine's capabilities, and using high-quality tools and materials. By implementing the strategies outlined in this guide, users can ensure their machines operate efficiently, produce accurate results, and have a long operational life. Trinkle Enterprise Co., Ltd., with its commitment to quality and customer service, stands ready to support its clients in achieving these goals, ensuring their CNC Plate Drilling Machines remain reliable assets in their manufacturing processes.