News

NewsComparative Analysis of Plate Drilling Machine, Rail Type Bridge Plate Drilling Machine, and Beam Line Drilling Machine

Comparative Analysis of Plate Drilling Machine, Rail Type Bridge Plate Drilling Machine, and Beam Line Drilling Machine

Introduction

In the competitive field of industrial manufacturing, precision and efficiency in drilling operations are crucial. Plate Drilling Machines, Rail Type Bridge Plate Drilling Machines, and Beam Line Drilling Machines represent advanced solutions in this area. Trinkle Enterprise Co., Ltd., a leader in manufacturing these sophisticated machines, combines innovative technology with years of engineering expertise to meet diverse industrial needs. This article provides a detailed comparison of these three types of drilling machines, focusing on their applications in manufacturing and how Trinkle Enterprise stands out in the market.

Company Overview: Trinkle Enterprise Co., Ltd.

Trinkle Enterprise Co., Ltd., with its commitment to quality and innovation, has established itself as a premier provider of industrial drilling solutions. Specializing in the design and manufacture of high-precision drilling machines, Trinkle Enterprise caters to various sectors, including construction, bridge building, and heavy machinery manufacturing. The company's dedication to technological advancement and customer satisfaction has positioned it as a trusted name in the industry.

Plate Drilling Machine

Description and Application

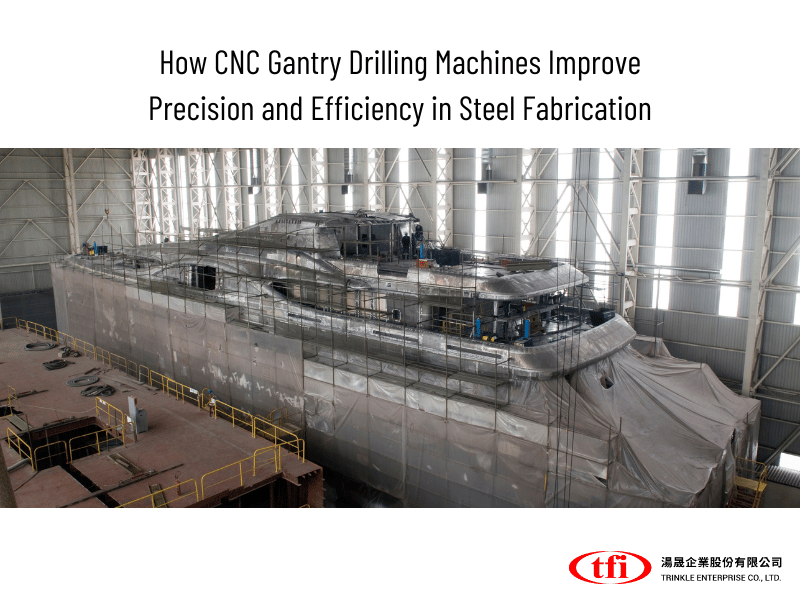

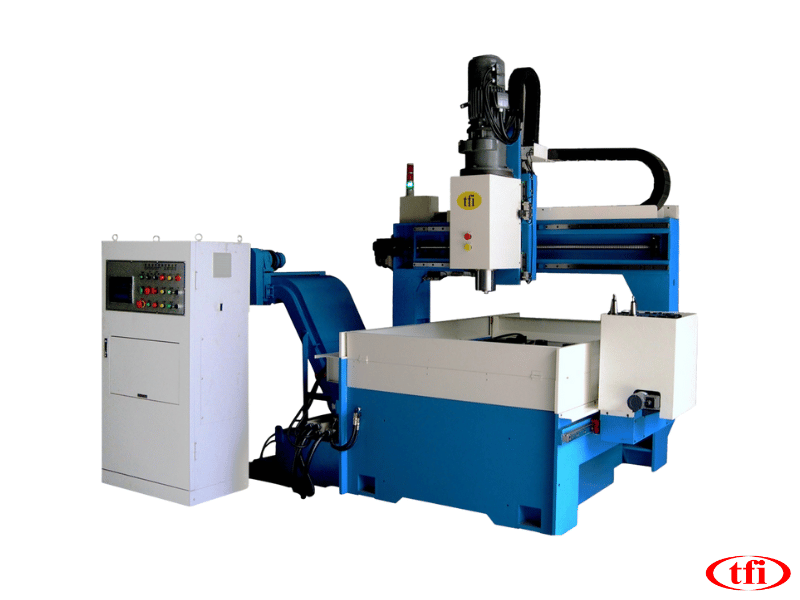

Trinkle's Plate Drilling Machines are designed for precision drilling in large metal plates, a common requirement in construction and shipbuilding. These machines can handle a range of materials, offering unparalleled accuracy and efficiency.

Manufacturing Application

These machines are instrumental in creating flange holes and intricate patterns in large plates, reflecting Trinkle's emphasis on versatility

Rail Type Bridge Plate Drilling Machine

Description and Application

Tailored for bridge construction, Trinkle's Rail Type Bridge Plate Drilling Machine excels in drilling operations for bridge plates. The integrated rail system facilitates smooth movement over large bridge sections for precise drilling.

Manufacturing Application

This machine is pivotal in bridge manufacturing, particularly in handling the drilling of expansive bridge sections, showcasing Trinkle's engineering prowess in specialized machinery.

Beam Line Drilling Machine

Description and Application

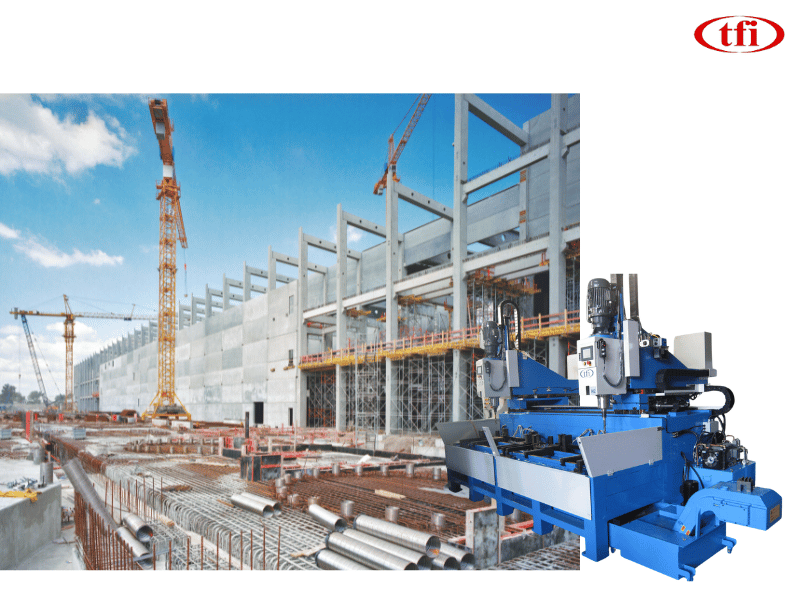

Specializing in drilling beams and structural components, Trinkle's Beam Line Drilling Machines are ideal for handling large, heavy beams in building frameworks and structural applications.

Manufacturing Application

These machines are essential for creating bolt holes in structural beams, demonstrating Trinkle's commitment to precision and multi-axis

Comparison among these three types of Drilling Machines

Versatility

- Trinkle's Plate Drilling Machines are versatile and adaptable, ideal for various industries.

- The Rail Type Bridge Plate Drilling Machines offer specialized functionality for bridge projects.

- The Beam Line Drilling Machines are optimized for structural beams, reflecting Trinkle's focus on targeted solutions.

Precision and Efficiency

All three machine types from Trinkle Enterprise are known for their high precision and efficiency, with the Beam Line Drilling Machines particularly notable for their multi-axis capabilities.

Application Specificity

While the Plate Drilling Machines are more generalized, the Rail Type Bridge Plate Drilling Machines and Beam Line Drilling Machines are highly specialized, catering to specific industry needs.

Conclusion

Trinkle Enterprise Co., Ltd. offers a range of drilling machines — Plate Drilling Machines, Rail Type Bridge Plate Drilling Machines, and Beam Line Drilling Machines — each with unique features catering to specific manufacturing applications. The selection of these machines depends on the work nature, material, and specific manufacturing process requirements, with Trinkle's commitment to quality and innovation evident across its product range.