News

NewsRevolutionizing Metal Fabrication: How CNC Plate Drilling Machines Are Shaping the Industry

Revolutionizing Metal Fabrication: How CNC Plate Drilling Machines Are Shaping the Industry

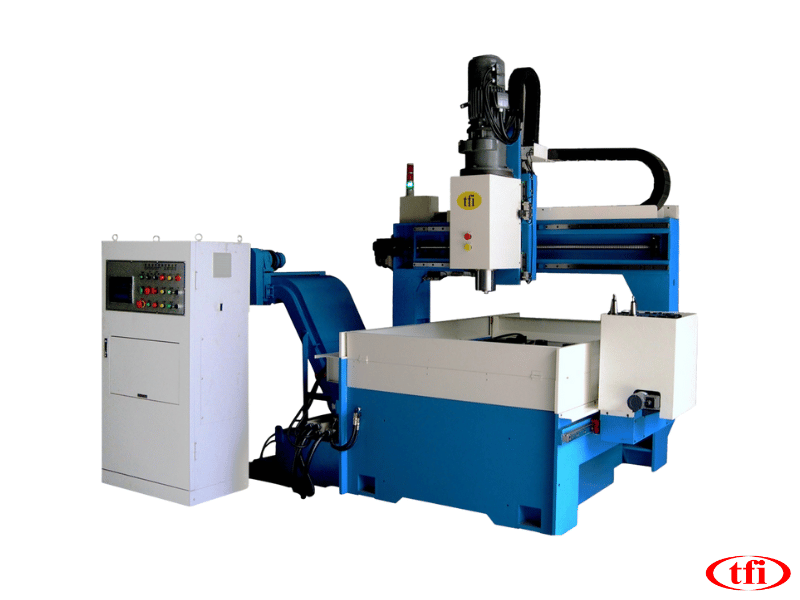

In the realm of metal fabrication, precision and efficiency are paramount. The ability to create complex, accurate holes in metal plates with speed and reliability can make or break a project. This is where CNC (Computer Numerical Control) plate drilling machines step into the spotlight. These powerful machines, such as the ones offered by "Trinkle Enterprise Co. Ltd." (https://www.trinkle-tw.com/en-US/plist1_1-dnc-series), have been revolutionizing the metal fabrication industry, reshaping the way we approach drilling and producing high-quality parts.

The Rise of CNC Plate Drilling Machines

Traditional drilling processes, often involving manual labor or semi-automated machinery, were time-consuming and prone to human errors. CNC plate drilling machines have emerged as a solution to these challenges, significantly improving the precision and productivity of metal fabrication. These machines are equipped with computer control systems that precisely dictate the drilling process, offering a range of benefits that are transforming the industry.

Precision Beyond Measure

One of the primary advantages of CNC plate drilling machines is their unparalleled precision. These machines can accurately position the drill bit to within fractions of a millimeter, ensuring that each hole is exactly where it needs to be. This level of precision is especially crucial in industries like aerospace, automotive, and construction, where the slightest deviation can lead to structural issues or compromised safety.

Trinkle Enterprise's CNC plate drilling machines are designed with cutting-edge technology to guarantee precision. Their DNC series, for instance, is equipped with advanced control systems and high-resolution encoders that deliver precise hole placement every time. This precision is a game-changer for industries that demand flawless results.

Streamlining Complex Operations

Complex hole patterns and drilling sequences are often required in metal fabrication. CNC plate drilling machines excel in handling these intricate tasks. Whether it's creating a series of holes with specific spacing or drilling holes of varying sizes, CNC machines are programmed to execute these operations with ease.

The CNC plate drilling machines from Trinkle Enterprise provide a platform for easy programming of complex drilling operations. The user-friendly software allows operators to input the desired hole patterns, sizes, and spacing, and the machine takes care of the rest. This not only saves time but also eliminates the risk of human error.

Efficiency Redefined

Efficiency is a driving force behind the adoption of CNC plate drilling machines. These machines work swiftly and consistently, greatly reducing the time required to complete drilling tasks. What might take hours or even days with conventional methods can be accomplished in a fraction of the time with CNC machines.

Trinkle Enterprise's CNC plate drilling machines are engineered for maximum efficiency. Their DNC series boasts rapid traverse speeds and tool change times, ensuring minimal downtime between tasks. This efficiency not only speeds up production but also reduces operational costs.

A Versatile Solution

CNC plate drilling machines are versatile, capable of handling a wide range of materials and plate sizes. Whether you're working with steel, aluminum, or other metals, these machines can adapt to the task at hand. This versatility makes them an asset to a variety of industries.

Trinkle Enterprise's DNC series offers a range of spindle options, tool holders, and other customizable features to meet the specific needs of different materials and applications. This adaptability is invaluable for businesses that deal with diverse materials and projects.

Cost Savings and Sustainability

CNC plate drilling machines offer more than just precision and speed; they can also lead to cost savings and reduced waste. Their precision means fewer mistakes, less rework, and reduced material waste. Additionally, the efficiency of these machines means that you can produce more in less time, increasing your overall productivity and profitability.

In today's world, sustainability is a growing concern. By reducing waste and energy consumption, CNC plate drilling machines contribute to more sustainable and eco-friendly manufacturing practices. Trinkle Enterprise's commitment to sustainability is reflected in their energy-efficient designs and responsible manufacturing processes.

Future-Proofing Your Business

Investing in CNC plate drilling machines from Trinkle Enterprise is not just about meeting current production needs; it's about future-proofing your business. The manufacturing industry is evolving, with demands for higher quality and quicker turnaround times. By embracing CNC technology, you position your business to thrive in this changing landscape.

Trinkle Enterprise continually updates and enhances their CNC plate drilling machines to keep up with industry demands. Their commitment to research and development ensures that your investment remains relevant and valuable for years to come.

Real-World Applications

To fully grasp the impact of CNC plate drilling machines, let's explore some real-world applications:

Aerospace Industry

In the aerospace industry, where safety and precision are paramount, CNC plate drilling machines play a crucial role. They are used to produce intricate parts for aircraft, such as wing spars, landing gear components, and engine mounts. The ability to consistently create precise holes ensures the structural integrity of these critical components.

Automotive Manufacturing

In the automotive industry, CNC plate drilling machines are employed to create holes for various components, including chassis and suspension parts. The efficiency and accuracy of CNC machines help automotive manufacturers meet the stringent quality standards required for passenger safety.

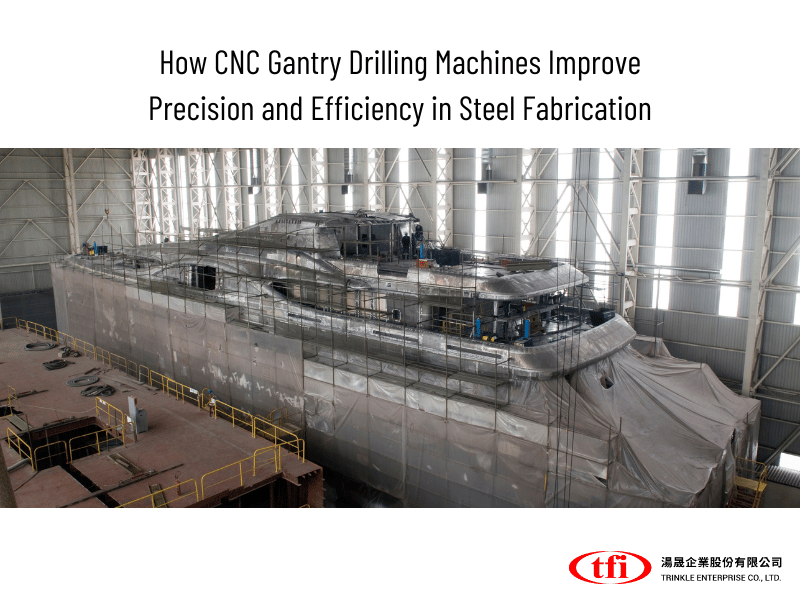

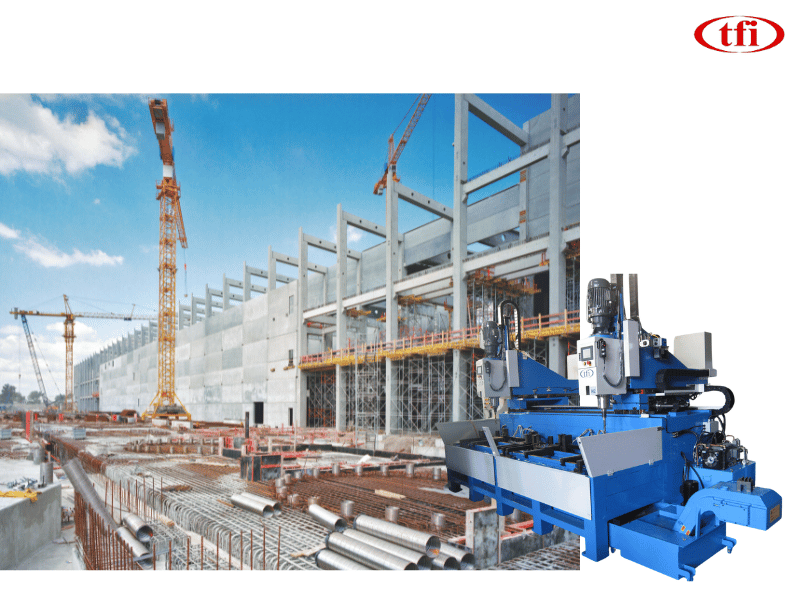

Construction and Infrastructure

The construction industry relies on CNC plate drilling machines for the creation of structural steel components. Whether it's drilling holes in beams, columns, or other construction materials, CNC machines ensure that these components fit together perfectly on-site.

Energy Sector

In the energy sector, CNC plate drilling machines are used to manufacture components for power generation and transmission. The precision of these machines is vital for creating high-quality components that can withstand extreme conditions.

Choosing the Right CNC Plate Drilling Machine

Selecting the right CNC plate drilling machine is a critical decision for any business. Trinkle Enterprise's DNC series offers a wide range of options to meet specific needs. When making this choice, it's essential to consider factors like the size and thickness of the plates you'll be working with, the materials you'll be drilling, and the complexity of the hole patterns you require. Trinkle Enterprise provides expert guidance to ensure that you select the machine that best suits your unique requirements.

Conclusion

The advent of CNC plate drilling machines, such as Trinkle Enterprise's DNC series, has ushered in a new era of precision, efficiency, and productivity in metal fabrication. These machines are not only changing the way we drill holes in metal plates but also how we think about manufacturing. With their precision, versatility, and cost-saving benefits, CNC plate drilling machines have become indispensable tools for industries that demand nothing but the best. As the manufacturing landscape continues to evolve, businesses that embrace this technology will find themselves at the forefront of progress, delivering high-quality products with speed and reliability. Trinkle Enterprise stands as a testament to this progress, providing cutting-edge CNC plate drilling solutions that are shaping the industry.