News

NewsCompare Gantry Drilling Machine and Plate Drilling Machine

Compare Gantry Drilling Machine and Plate Drilling Machine

The CNC gantry drilling machine is a type of metal cutting machine tool that can do drilling, hole processing, auxiliary milling, boring, and tapping; whereas drilling a hole through a steel plate is a cold cutting process in which a plate drilling machine is used to create or enlarge a circular hole in the material.

Typically, the drilling machine is a rotary cutting tool with multiple points pressed against the steel and turned at thousands of revolutions per minute.

Gantry Drilling Machine

CNC gantry machines come in a wide range of sizes and are typically used for fabricating steel and aluminum sheets, flanges, and tube plates.

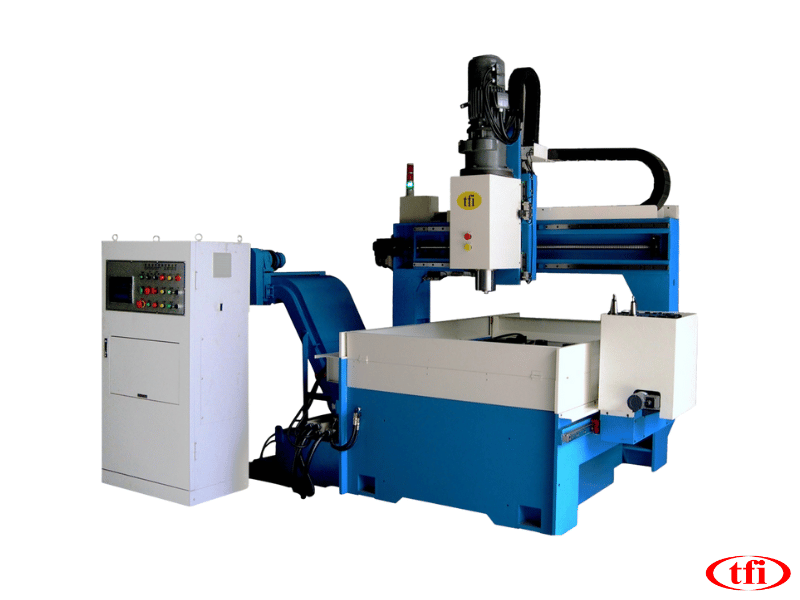

Gantry CNC milling machine center is distinguished by its boxy, compact design; this makes it an excellent choice for shops with limited floor space, and the machine's one-piece work table and columns ensure a steady, rapid feeding performance that can handle the deman ding tasks of cutting precise molds and aluminum.

The GS CNC gantry-type machining center's high-powered spindle and optimal structural arrangement allow for rapid production rates, resulting in a flawless finish in the allotted time. There is a maximum cutting feed rate of 24,000 mm and fast movement along all thre e axes.

- Gravity is distributed in a pyramid pattern via the spindle, ran, cross beam, and bed of this design and the columns, bed, and table are all cast from a single mold.

- In order to guarantee precise placement even during rapid motion, the X-axis is equipped with two linear scales and two servo motors powered in parallel.

- Directly driving the Z-axis with a servo motor eliminates the possibility of errors caused by indirect driving between mechanisms, reduces energy use, and boosts the effectiveness of the Z-motion axis.

- Excellent work-piece surface accuracy can be ensured using a spindle that is directly driven after rapid cutting, with minimal distortion, backlash, vibration, and energy consumption.

- Users will be thankful for the small table height, the closer operation zone, and the wider door width.

- The conventional chain-type chip conveyor is capable of efficiently removing iron chips.

Plate Drilling Machine

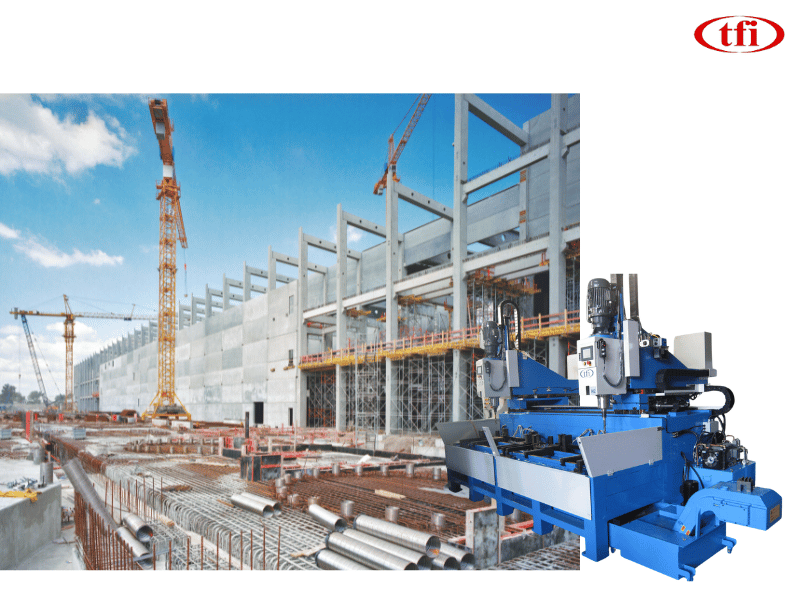

A CNC-controlled Plate drilling machine is included in the extensive array of goods for drilling, welding, cutting, fabrication, and its associated automated items. We have been designing, conceptualizing, manufacturing, welding, and handling automation solutions for diverse business segments and customer bases since 1995.

We have just started using a plate drilling machine to improve the quality of service that we provide to our existing customers in the beam fabrication and other steel fabrication industries.

In addition to serving the fabrication business, the machine also provides its services to the boiler (heat exchanger) industry,

- the water purification industry,

- the ship construction industry,

- other sectors with plate drilling requirements.

We provide a wide range of products, including a simple plate drilling system to an advanced beam drilling machine.

This machine can drill holes on the web and flange plate to perform straightforward end flange drilling on beam plates to large plates.

Plates of several types, including Full Plates, Cut Plates, and Profile Plates, can have holes drilled in them.

This machine has been installed with the most up-to-date control architecture, which integrates industry-standard CNC controls, high-precision servo motion control, and G code compatibility. It is highly customizable to fulfill the customer's requirements.

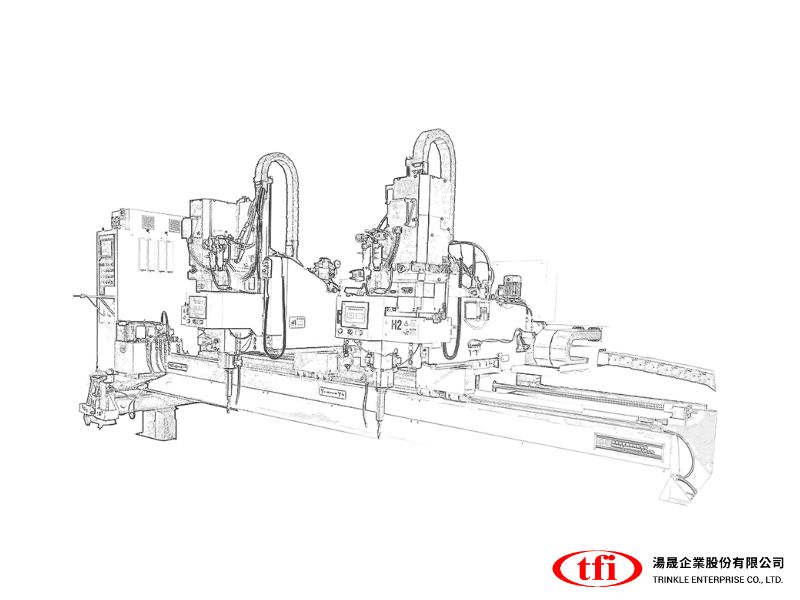

Gantry CNC plate drilling machine with high speed.

- Depending on the application, the gantry mobile high-speed CNC plate drilling machine can use either high-speed steel twist drills or hard alloy internal cooling drill bits.

- Flanges, heat exchangers, and tube sheet sections are the most common objects it is used to process.

- High efficiency, precision, straightforward programming, and easy operation are key hallmarks of numerical control machining.

- The CNC plate drilling machine has a rigid precision spindle in its drilling power head box. Spindle with built-in BT50 thermal management system.

- The accuracy of the carbide internal cooling drill is quite good.

- Combines a hydraulic cylinder with a knife for swiftly loading and releasing tools.

- A high-powered spindle servo motor transmits torque to the spindle through a synchronous belt. Spindle speeds range from 30 to 3000 revolutions per minute.

There is a wide variety of CNC gantry and plate-drilling milling machines available. Please look at our top-quality Drilling Machine, and visit our store for a wide range of options.

FAQ:

1. What exactly is a drilling plate?

Holes in steel plates can be created or enlarged by employing a drill bit and the cold-cutting procedure. The drill bit is a multi-pointed rotary cutting instrument pushed into the steel and turned at high speeds.

2. What is the gantry machine type?

Weight is distributed in a pyramid pattern via the spindle, ran, cross beam, and bed of this design and the columns, bed, and table are all cast from a single mold. In order to guarantee precise placement even during rapid motion, the X -axis is equipped with two linear scales and two servo motors powered in parallel.

3. What is a gantry plate drill?

A CNC gantry plate drill is a specialized CNC machine used to drill connecting boards and foundation plates in steel structures, towers, bridges, and other industries.

4. What are a drilling machine and its parts?

A drilling machine consists of the following primary components: a stand, shaft, bit, and spindle. Depending on the design, the cast-iron bottom can rest on a seat, a pedestal, or the floor. The floor is where you'll find the more powerful and heavier machines. The column is placed in a vertical position on top of the base.

5. What are the many types of drilling machines?

There are several types and designs of drilling machines, but most drilling machines fall into four main types: vertical, horizontal, rotary, and special purpose.

We have qualified staff who can advise you on standard and bespoke orders. Don't hesitate to get in touch with us for a free estimate!