News

NewsTypes of Drilling Machines

Types of Drilling Machines

Drilling machines come in a wide variety of shapes and sizes, but they can be broadly classified into four groups: upright sensitive, upright, radial, and special purpose.

A drill press or drilling machine is a staple of any quality machine shop. A drill press is a device used to drill into a workpiece by turning and advancing a rotary tool. While its primary function is to bore holes, a drill press may do a variety of machining tasks with the right attachments. Drilling, reaming, tapping, deburring, countersinking, and spot facing are the most typical forms of machining accomplished using a drill press.

7 Types of Drilling Machines:

Drilling machines are divided into seven types based on their design and function.

1. Portable drilling machine

To drill holes up to 12 millimeters in diameter on any surface, a portable drilling machine can be utilized. It can bore holes in a wide variety of materials, including wood, plastic, metal, and even concrete.

Portable drill machines are utilized by many different tradespeople because of their portability and versatility.

2. Bench Drilling Machine

You may use this benchtop drill machine to bore holes in many materials, including wood and metal. Boring, reaming, and taping are just a few of the many types of cutting operations available to you.

To drill holes in steel up to 12.5 mm in diameter, use a machine of this type. In addition, it sees extensive use in the construction and manufacturing sectors.

In light of the capabilities it offers, this tool has another name: a sensitive drilling machine. The skill of feeling the drill bit move as one works.

3. Pillar drilling machine.

Drilling holes between 20 and 40 millimeters in diameter in metal and wood is no problem for a pillar drill machine, sometimes called an upright drilling machine. It reminds me of a bench drill in appearance. On the other hand, it features a stronger motor and higher drilling capacity than a standard bench drill.

The majority of this tool's users are in the manufacturing and professional woodworking sectors. Drilling, reaming, reaming, tapping screws, spot-facing machining, and batch manufacturing are all possible with a pillar drilling machine.

4. Radial drilling machine.

The drill bit's height above the workpiece can be adjusted by rotating, raising, and lowering a radial arm located on a vertical pillar on this machine.

Its primary application is in industrial machine shops, where it is used to bore holes up to 80 mm in diameter in substantial materials.

5. Gang drilling machine.

A gang drill machine, also known as a multi-column drill or a column drill, is a drill that has many drill heads and columns on a single table.

Useful for making multiple holes in a piece of metal simultaneously. This machine can execute a wide range of machining tasks, including drilling, reaming, counter-drilling, and tapping.

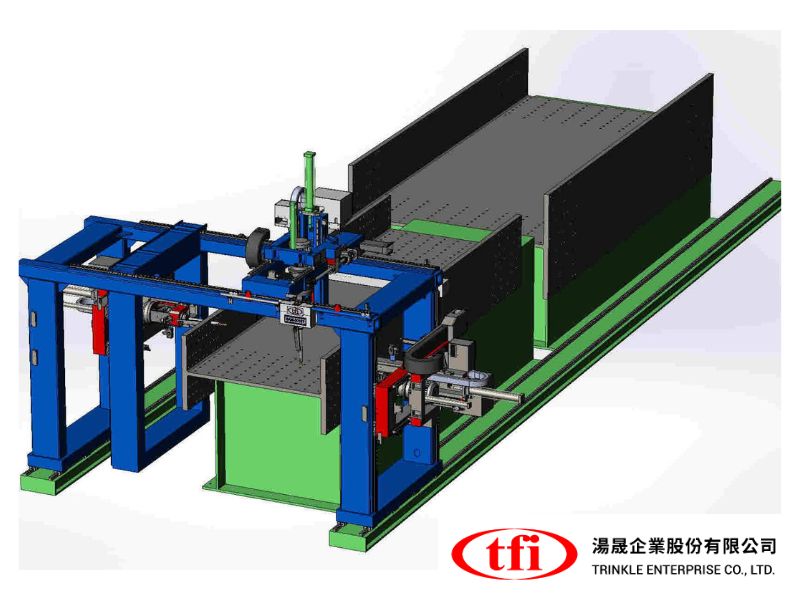

6. Multi-spindle drilling machines.

The drill head of this unique equipment has multiple spindles that are all powered by the same motor. Drilling many holes at once is a frequent practice in factories.

The multi-spindle drilling machine's primary goals are to speed up production and cut down on labor costs.

7. Deep hole drilling machine.

For applications like drilling spindles, cylinders, connecting rods, and specialized oil-well drilling equipment, this type of drilling machine is ideally suited.

What are the uses of drilling machines?

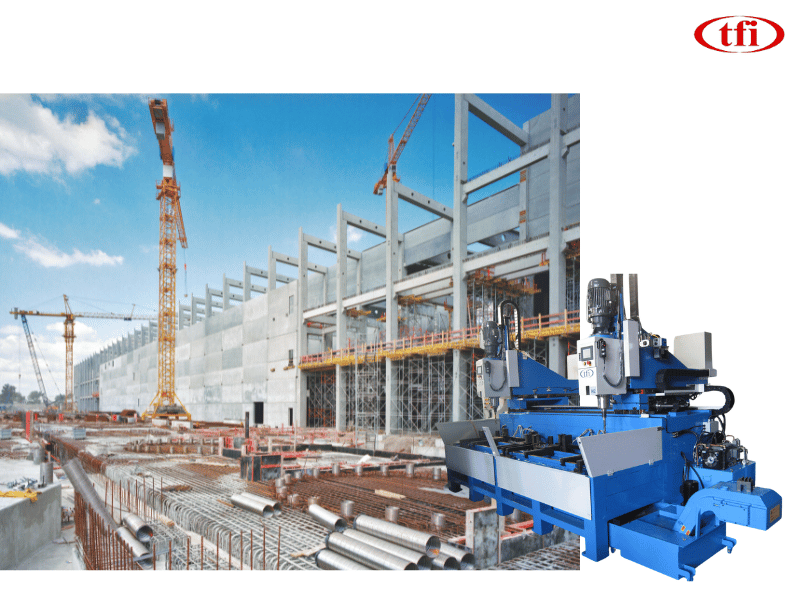

Aside from the building industry, the drilling machine can be used to make medical items, autos, and electronic products. You may use a drill for anything from making holes in concrete to shaping metal because they come in so many shapes and sizes. The drill's performance can be modified by adjusting the electric motor, spindle speed, spindle nose, and spindle travel. So, it's important to get a drill press that works for the client and their industry.

Which type of drilling machine will you choose?

At this point, all you need to do is decide which of the many excellent drilling machines available is the best fit for your needs.

Choose the appropriate tool and drill something, no matter how big or small it is.

However, choosing the right drilling machine for efficient work is critical. We hope this information has given you a better grasp of drilling machines and how they differ. When selecting drilling machines, remember this information to help you identify which equipment will work best for you.

Best of luck for Drilling!

FAQ:

1. How many types of drilling machines are there?

Drilling machines come in a wide variety of shapes and sizes, but they can be roughly categorized into four groups: upright sensitive, upright, radial, and special purpose.

2. What are drilling tools?

Drilling tools are end-cutting tools that are used to create holes in a workpiece. A drilling tool's shank contains flutes, or grooves, that allow fluids to enter while also ejecting the cut ships from the workpiece.

3. What is a drilling process?

By using a rotating cutting device, holes are drilled into the solid substance being worked with. When you drill your hole, you can use this indentation as a guide by following its contours. The process of creating or enlarging a hole in a solid substance is referred to as drilling, and the instrument that is used for this purpose is called a drill bit.

4. What are drill bits called?

A unibit (also known as a step drill bit) is a drill bit that has a stairstep profile and is roughly conical in shape. This bit is versatile in that it may be used to drill holes of varying sizes. Some pieces eventually reach a conclusion and can be used alone. The larger diameter bits have rounded tips and are used to enlarge existing holes.

5. What is mechanical drilling?

Various laminate materials can be mechanically drilled through with the use of a spinning bit tool. Micro-grain carbide is commonly utilized to make the bit, which allows the drill to be used again. They can be reused after being sharpened, typically up to three times.

Contact Trinkle if you have any questions!