News

NewsWhat is a Drilling Machine?

What is a Drilling Machine?

What is a Drilling Machine?

A drilling machine is a useful tool for rotating and extending rotating holes into a workpiece to trim the round hole into metal, plastic, wood, or other solid materials.

The drilling machine benefits drilling and a wide range of other machining operations. A drilling machine can perform plane digging, step drilling, core drilling, boring, counter boring, placing, spot facing, and tapping.

Drilling machines are commonly used in cutting wood, metal work, renovation, manufacturing, construction, and mobility projects.

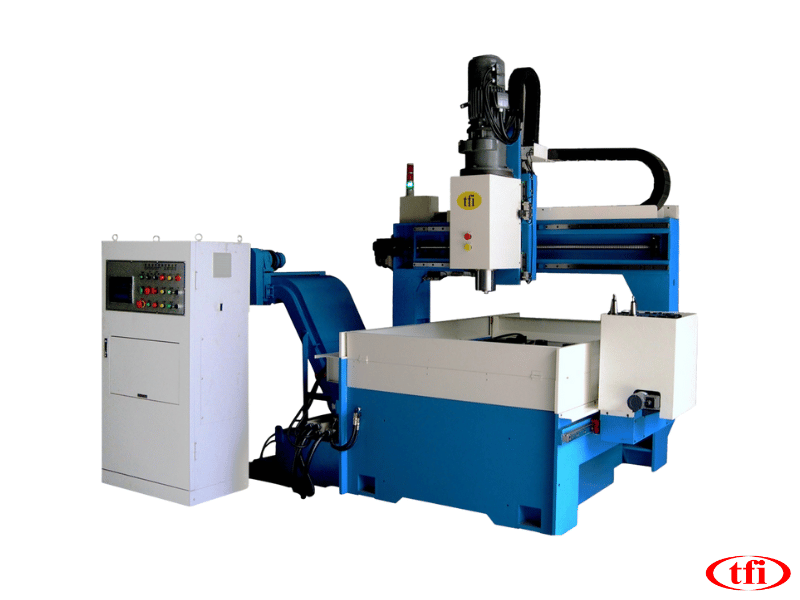

Parts of a drilling machine

The following elements are typically present in a drilling machine, individually or in combination.

- Base

The drilling machine's base is generally locked to the ground to support its load.

- Column

It can support the arm, drill head, and rolling table when placed on one side of the base.

- Cantilever

The arm, located on top of the column, holds the drill head and the drive shaft shelter.

- Drill Head

A drill head is a driving mechanism fixed on one side of the cantilever. It can move up and down.

- Worktable

It is a column-mounted table that can be shifted vertically and horizontally.

- Feed Mechanism

Feeding mechanisms involve manual and automatic feeding via an electrical motor.

- Spindle

It is a set position in a casing that handles the drill or cutting tool.

- Chuck

The chuck keeps the drill cutting tool in position, which is placed on the spindle.

- Electric Motor

Electric motors used in drilling machines must be high starting torque, high speed, and lightweight.

How does a Drilling Machine work?

When the motor is turned on, the spindle rotates, as does the tried-to-step handle to which it is connected. Another steep roller is attached to the extreme side and can be inverted to increase or decrease the rotational motion's speed.

A V-belt is now organized between the steep rollers to drive power transmission. To increase power efficiency, a V-belt was used rather than a flat belt in this case.

The drill bit in the chuck and connected to the spindle now rotates. The spindle rotates with the Rollers, which usually causes the drill bit to turn.

The spindle rises or falls in the vertical direction as the hand-wheel is turned, providing a sufficient amount of food to work, and this drill string is used to make the holes on the element held in the drilling machine.

Types of a Drilling Machine

There are different types of Drilling machines available on the market, each with unique attributes, features, and uses.

- Compact Drilling machine

A collector is used to grip the piece to be drilled while the machine's prime mover digs a hole in rocks or any rigid surface.

- Sensitive Drilling machine

Drill heads, rollers, worktables, driving mechanisms, and columns are generally included in a single machine. A hand-fed drill is used to begin the process.

- Radial Drilling Machine

To support a wide range of altitudes, the table has been structured. Instead of moving the part to the tool, the spindle can be flipped over the workpiece, allowing the device to generate crisscrossing and angular holds in only one setup.

- Pillar Drilling Machine

A more effective and larger drilling machine is required for moderate to too big holes.

- Deep mole Drilling Machine

It is designed especially for drilling large holes in mechanical components, slots, and other elements at a high cutting speed and low flow rate.

- Multiple spindles Drilling Machine

This machine can drill thousands of holes into a single sheet and the same holes on a range of different parts.

- CNC Drilling Machine

A computer quantitatively monitored drilling machine can automatically switch devices when using a baseplate or fully automated tool switcher. The software controls the speeds, feeds, and table position.

- Micro Drill Press

Its high flow rate and reliability make it ideal for influencing tiny parts.

- Turret type drilling Machine

The tool can be vastly adjusted into position because it is designed with several drilling heads installed on a ring.

- Gang drilling machine

This machine could be used for drilling, deburring, drilling, and pressing by simply moving it back and forth.

The Function and Importance of a Drilling Machine

A most popular machine tool is the drill, or in other words, a drilling machine, which most people are most familiar with. It is one of the essential tools in the workshop because it decreases the amount of effort required by the workers. It ranks just below the lathe machine in terms of meaning and worth.

Although it was initially supposed for boring, slotting, and drilling, it can also perform various other tasks at a low price. Rotating edges of the tool create an excellent finish hole when the force applied to the work (or material like wood, metal, or cement) is imposed on the tool's base.

A drill machine's primary function is to produce holes of various sizes in hard materials, but specific drills are only suitable for use in certain industries. It can drill a hole in solid materials with high accuracy and precision, and it needs less manual work on the part of the design unit.

Artisans use a particular type of drill called a hammer drill to make holes in wood. Battery-powered drills, on the other hand, can be used in scenarios where an electrical supply is not possible. In industrial applications, a drilling machine, also known as a pillar drill, can be used to large-scale drilled materials in various sizes and shapes in large amounts.

For heavily loaded construction projects, horizontal drilling machines are the easy tool of choice because of their easiness of use in machine innovation. Drilling machines are essential tools used in various areas, but their features play a significant role.

The self-carrying structure provides flexibility and convenience in the workplace. Because of their widespread use, these drill machines are well-organized and require little maintenance. Drill machines have a lot of dimensional power due to the massive distance between their locations.

Drill machines are generally used in high-power mode, enabling them to handle a wide range of materials easily. Additionally, machine solidity can sometimes include resistance to the absorption of mistakes and external force.

We hope this article was helpful in your knowledge of high-speed drilling machine. No matter what you choose, we wish you the best luck with your new machine.

To learn more about milling head, contact TRINKLE today!