News

NewsDifferent Parts of a CNC Gantry Drilling Machine

Different Parts of a CNC Gantry Drilling Machine

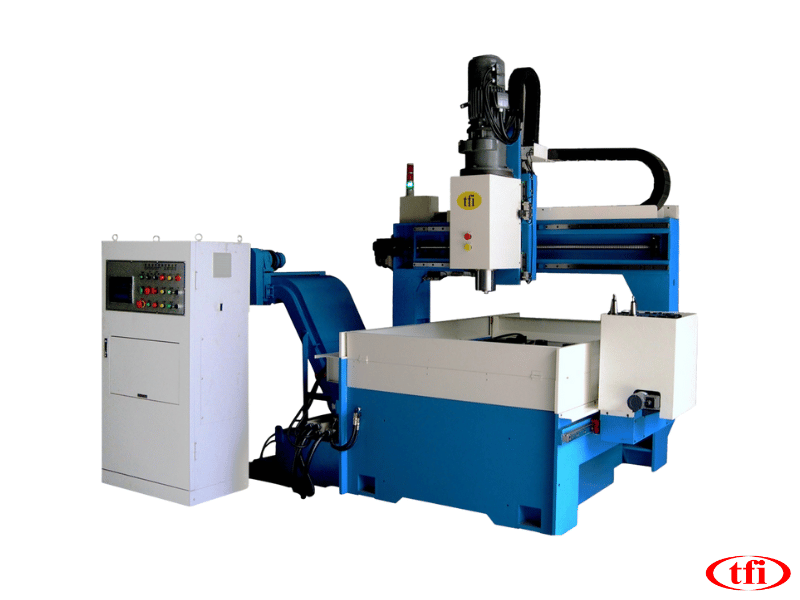

The CNC gantry drilling machine belongs to the category of metal cutting machine tools whose functions include drilling, hole processing, auxiliary milling, boring, and tapping. It is primarily used for the high-efficiency drilling of flanges, flat plates, rings, disks, and other types of workpieces with thickness that is within the effective range.

Blind holes and drilling through holes are made possible on composite materials and single material parts. The machine tool has a digitally controlled machining process and a very convenient operation. It can realize mass production, multiple varieties, high precision, and automation.

The following make up the structure of a CNC gantry drilling machine:

Bed

The bed is a critical part of the structure, finished by the secondary annealing treatment. It has no deformation and has static rigidity and good dynamic. There is a working table that adopts the casting structure, as well as a T-slot that has the reasonable layout for finishing on the plane used for clamping the workpiece.

There is also a drive system adopting the precision ball screw and AC servo motor pair for driving on both sides to create the gantry move in the direction of the X-axis. The adjustable bolts get distributed on the bed’s bottom surface that easily adjusts the level of its worktable.

Drilling Power Head

This drilling power head takes on a dedicated servo spindle motor that is driven by the toothed synchronous belt deceleration for increasing torque for driving the dedication precision spindle. This spindle adopts the rear two and front four six rows of the Japanese angular contact bearings for achieving stepless speed change.

This spindle is equipped with a pneumatic tool change system for making the tool. It is an easy and quick replacement, with the feed driven by a ball screw and servo motor. The Z, Y, and X axes can also be linked, adopting the semi-closed loop control for realizing circular and linear functions of interpolation.

Mobile Type Gantry

A movable gantry is processed and cast by gray iron. There is also a pair of ultra-high capacity rolling linear guides installed on the gantry’s front side. The servo motor and precision ball screw pair make the powerhead slide move in the direction of the Y-axis, with the drilling powerhead installed on powerhead side. The gantry’s movement is made possible by the ball screw’s rotation driven by servo motor through precision coupling.

Moving Sliding Saddle

A sliding saddle is the precision cast-iron structure. This is equipped with a set of precision ball screw pairs, two ultra-high load-bearing CNC guide rail slides, and the high precision planetary reduce that is attached to the servo motor for driving the drilling powerhead.

By moving in the direction of the Z-axis, it allows the powerhead to work forward, fast forward, stop, fast reverse, and more. This also has the functions of automatic chip removal, pause, and chip breaking.

All of these parts of the CNC gantry drilling machine work together for the overall function of the equipment and deliver great results.

- Products

- Plate Drilling Machine

- Rail Type Bridge Plate Drilling Machine

- Beam Line Drilling Machine

- Laser Marking Machine

- Beam line stamper

- H-Beam Scallop & Beveling machine

- Plate beveling machine

- Auto Arm Welder

- Pipe Notcher

- Drill Grinder

- Magnetic Core Drilling Machine

- Remolift

- Shear Wrench

- H-Beam Rotater