News

NewsWhy do people prefer gantry drills?

Why do people prefer gantry drills?

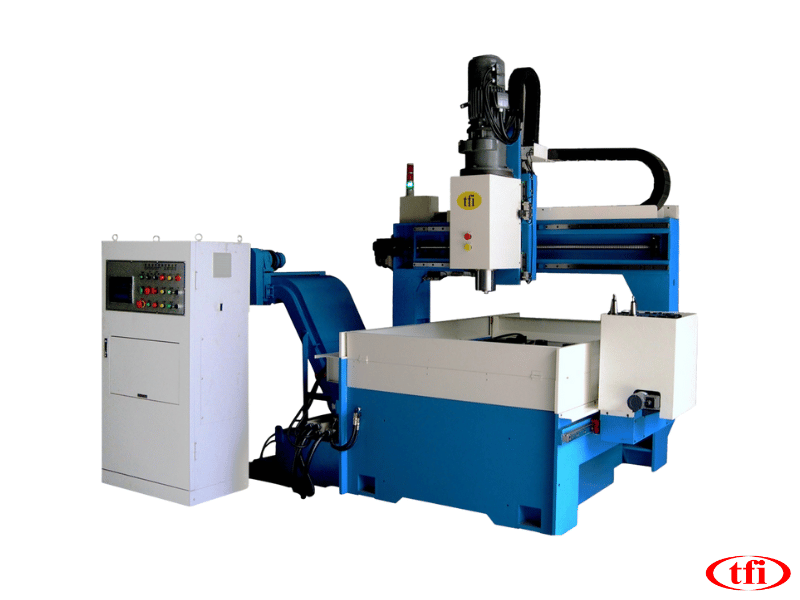

CNC is an abbreviation for Computer Numerically Controlled, which signifies that the computer is controlled numerically. Machine tools such as lathes, milling machines, drilling machines, and other similar devices may use this new functionality, which is widely available. Because of the support of a computer, they may boost their working capacity and efficiency.

The fact that some of these gantry drills are still operated by hand means that employees do not have time to rest or devote their attention to other tasks while they are working on them. Computer numerical control (CNC) machines are highly respected because they deliver high average precision and accuracy, and time efficiency in a small container.

CNC Gantry Drilling Machine:

The following benefits of using a Gantry Drill over a conventional Radial Drill are available.

- CNC control with a lot of punch

- Drilling takes much less time.

- Unparalleled accuracy

- Mark-up time has been reduced.

Advantages of gantry drills:

Below are the advantages of gantry drills,

- Better precision and accuracy are achieved using this tool.

- Mistakes in cutting conditions or in dimension may be corrected with relative ease.

- The reduction in the number of employees necessary helps to reduce labor costs.

- CNC machines can generate complex designs with great precision in the shortest amount of time.

- It also has a practical purpose in terms of safety.

- It is not necessary to have a highly competent operator.

- This machine is capable of doing the conversion of the unit with ease.

- It is capable of diagnosing its malfunction. Specialized software makes it simple to diagnose when the CNC system fails to run. It also can assist in the maintenance and repair of the system on an automated basis.

- In addition, it has an online editing application, which means that any changes and modifications made by the component data are stored in the computer rather than being sent back to the tape for reprocessing.

- Low-maintenance requirements are necessary.

- The CNC machine provides a higher level of production and capabilities.

- It has a high level of dependability.

- Reduce the number of setup changes over time.

- It has the capability of operating 24 hours a day.

Rapid prototyping software is available:

CNC machines were the first big breakthrough in fast prototyping, and they have remained such until this day. In the past, components had to be machined by hand before numerical control (as in the case of punched tape technology) or computer numerical control (as in the case of analog and digital computers).

There were inevitably greater margins of error in the final prototype items, which was exacerbated even more when gantry drills were manually operated for larger-scale manufacture. The greater accuracy that CNC machines provide has revolutionized the manufacturing industry's capacity to prototype various materials, components, and other equipment swiftly.

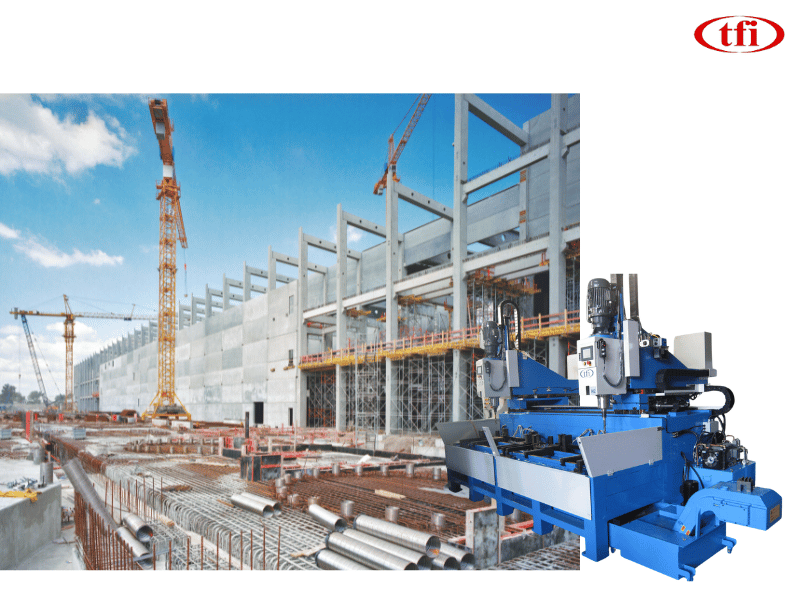

Application in the Manufacturing Industry:

Many new CNC specialized machines are designed expressly for niche production processes and are available for purchase today. Electrochemical machining, for example, is used to cut very durable metal items that would otherwise be impossible to cut. Gantry drills are better suited for prototyping and are thus more often employed for this purpose than production.

- Products

- Plate Drilling Machine

- Rail Type Bridge Plate Drilling Machine

- Beam Line Drilling Machine

- Laser Marking Machine

- Beam line stamper

- H-Beam Scallop & Beveling machine

- Plate beveling machine

- Auto Arm Welder

- Pipe Notcher

- Drill Grinder

- Magnetic Core Drilling Machine

- Remolift

- Shear Wrench

- H-Beam Rotater