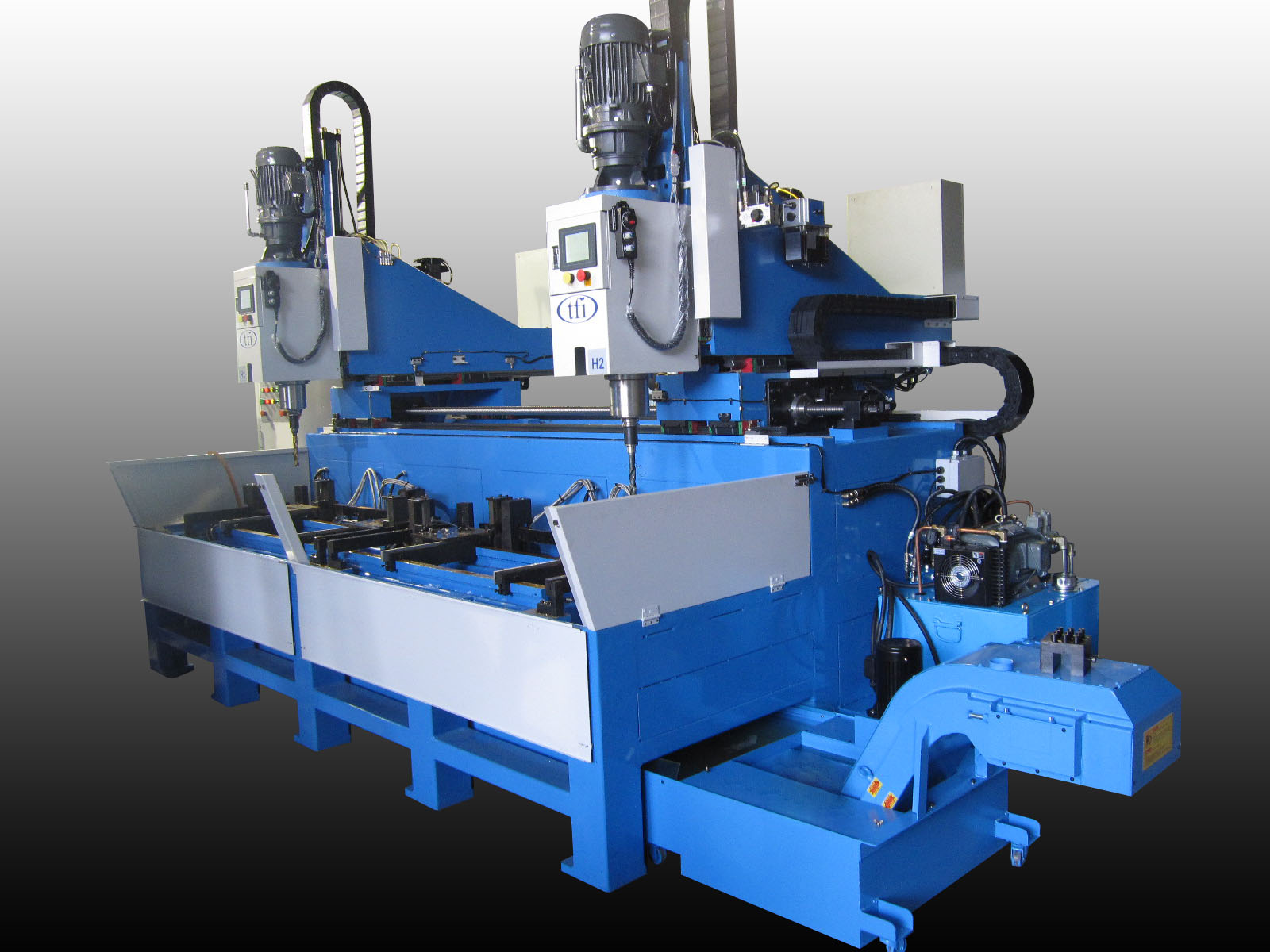

Two Hydraulic Pumps

Stable to clamp on 2 different areas

Operation Protection Buttons

Spindle not move to working area when loading/unloading workpieces

Auto Measurement on Drill Length

Auto measuring device → Fast, precise and convenient

Save time and no inaccuracy measuring tolerance

High Speed Drilling

High-rigid machine & efficient coolant system 0.35 mm/rev & 2.0 mm/sec when drilling Ø 28

Multi-Location Process(option)

10 kinds of same/different jobs or 20 processing locations for smaller workpieces

Auto-process 20 piles of workpieces after working-hours

Auto Power-off

Programmed auto power-off after last process cycle

Auto Lubricating System

Auto lubrication feeding → Longer life

Servo-Driven Tool-Feeding

Servo-driven tool-feeding

→ Stable in high-speed

Decelerate to give longer tool life when tools on surface of workpiece

Higher speed in workpieces

Servo-Driven Tool-Feeding

Servo-driven tool-feeding

→ Stable in high-speed

Decelerate to give longer tool life when tools on surface of workpiece

Higher speed in workpieces

Graphic-Pattern-Dialogue Input

100% of drilling patterns in the program

Only 30 min. to learn to calculate, preciously up to 0.001

TK-33 Specialized Step-Feeding (Option)

High rigid frame body

Drill-grinder

→ Continuous step-feeding

Drilling as fast as advanced Japanese machines

Processing Multi-Hole Connecting-Plates for Bridges

Suitable for a dozen of multi-hole groups

High Rigid Structure Designing

High rigidness and reinforcement in main frame and strength in accessories

Longer life with no vibration in high speed drilling or bigger holes drilling

Fast-Marking

Fast-marking to locate holes

Position Check or Supports Adjustment

Laser cross to recognize markings

Position Check or Supports Adjustment

Marking checking before loading workpiece in order to adjust supporting positions avoids drilling to damage the error-placed supports

High Torques & Revolutions Motor

TECO Motors → High torques for bigger diameters.

High revolutions for smaller diameters

Cranes of Lightweight & High Performance (Option)

German ABUS HB Crane to lift all workpieces

Built-in Teflon wheels → Lowest resistance 0.001

Easy Re-Start

Press button Previous/Next Hole to continue process

Fast restart on unfinished hole when stopping during auto operation

High Quality Controlling System

CPU controllers, panel system, servo system, 1/0 panel, frequency converter, magnet contactors, and buttons/keys in controlling system are leading Japanese parts

Laser-Center Holes Checking (Option)

Patented design for cross center of drill, graph-recognition, teaching and inputting → Time-saving, preciousness & convenience

Products

Products